The contemporary industrial scenario is marked by unprecedented dynamism, driven by companies of all sizes that face constant challenges, from the need to optimize operational efficiency to the demand for adaptability in the face of volatile markets and rapidly evolving technologies.

The Nexto NX series, brings together high-embedded technology and was designed for distributed and redundant control for the industry's most advanced processes

This article proposes an in-depth analysis of the NX series' innovations, its modular and flexible architecture, its applications in strategic markets, and its differentials, such as the embedded Linux platform, Docker support, a wide variety of advanced protocols, and remote access features, essential elements for implementing new industrial trends.

High performance with scalable power

NX CPUs provide exceptional performance with powerful 32 and 64-bit RISC PowerPC and ARM processors, capable of executing complex calculations and advanced control functions with impressive speed. The ability to process more than 145,000 boolean instructions or up to 500 PID loops per millisecond demonstrates the ruggedness of the NX series, enabling it for the most demanding and high-speed applications. This processing capability allows NX equipment to handle control algorithms with rigorous real-time requirements, fundamental for advanced applications such as high-precision motion control, high-speed packaging systems, or chemical processes that require rapid adjustments.

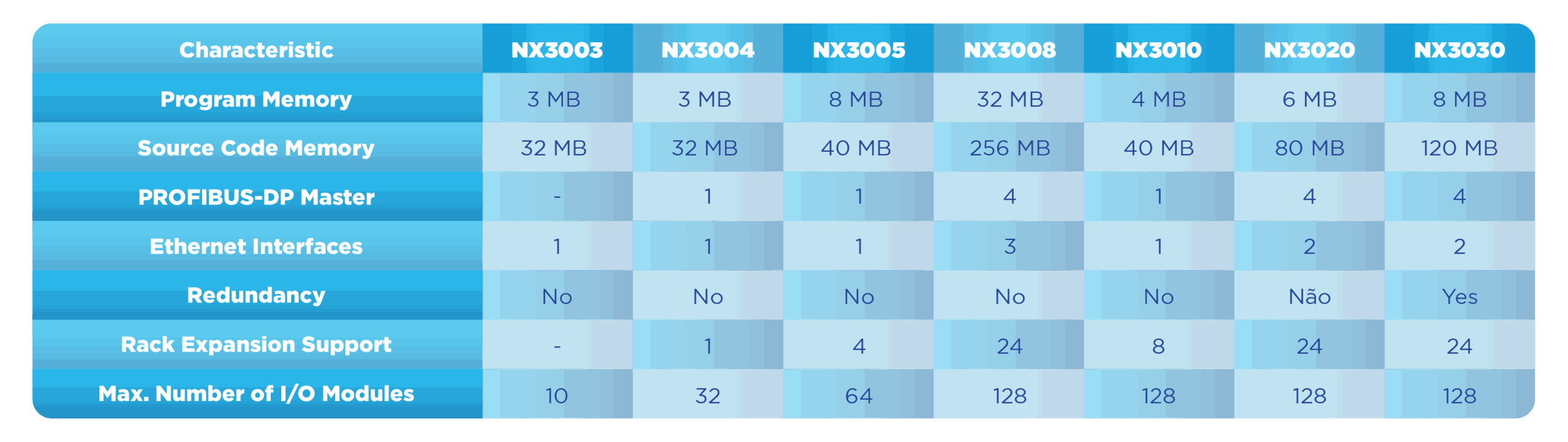

The flexibility is also a hallmark of the NX series’ architecture, which is based on deterministic Ethernet to ensure consistent and lossless performance. The internal bus can be expanded across multiple remote racks, allowing a single CPU to control up to 320 I/O points in a single local rack and up to 24 remote racks. This expansion capability without performance loss offers an adaptable solution for any application size or complexity, from small machines to large distributed industrial plants.

In the industrial environment, companies often start projects with a certain scale and, over time, expand their operations or need to integrate systems in different locations. A modular and distributed architecture like that of the NX series’ allows for phased expansion and the integration of systems in large or geographically dispersed facilities, without the need for a complete system replacement. This reduces the risk of obsolescence and protects the investment, offering a solution that adapts to the growth and evolution of needs.

An example of the series’ capability is the NX3008 CPU.Equipped with a 1 GHz 64-bit ARM processor, it is scaled for the control of machines and processes ranging from small to large.

Check below a detailed overview of the NX CPUs:

The NX series stands out not only for its performance and scalability, but also for its embedded innovation and intelligent features that transform industrial operations.

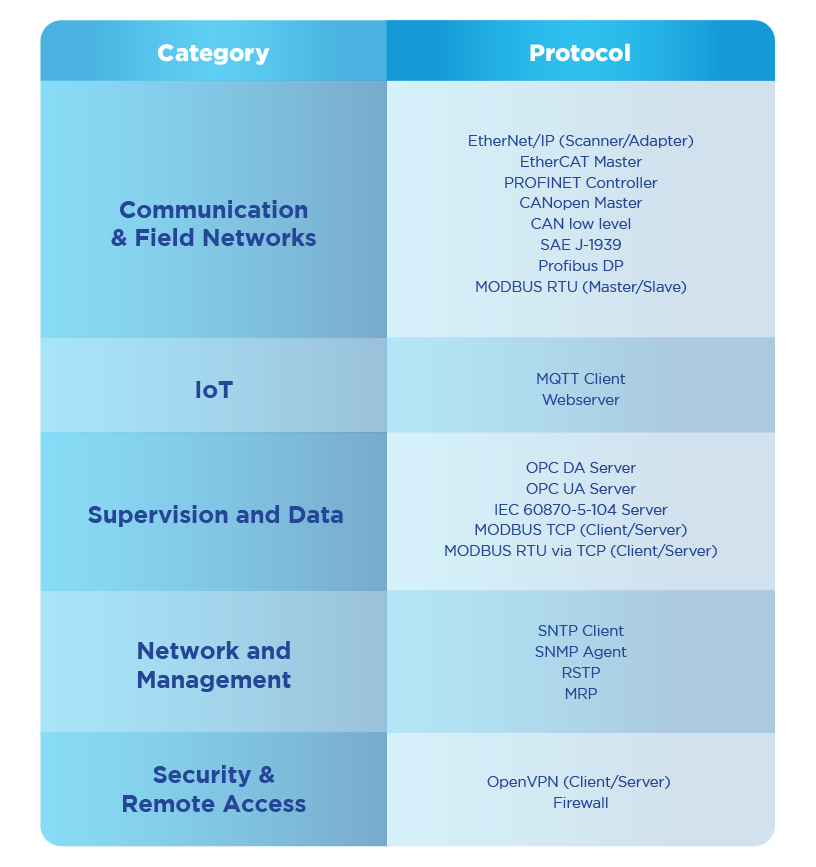

The series supports a wide range of communication protocols, ensuring compatibility with existing and future systems. This includes EtherNet/IP, OPC UA, MQTT, CANopen, CAN, Modbus (RTU, TCP), EtherCAT, IEC 60870-5-104, SNTP, SNMP, and PROFINET, and connectors for Microsoft SQL Server databases. This diversity ensures that the NX series can act as a central hub in any industrial environment, regardless of the vendor or communication standard. In environments where the coexistence of different generations of technology is common, this capability is essential, as it simplifies the entire system architecture, reducing complexity and integration costs.

Main supported protocols:

Security and remote operational flexibility

The embedded VPN in the series creates a private and highly secure tunnel for direct connection to the CPU. This functionality allows remote and secure access to the entire control network to access systems securely from anywhere for diagnostics, configurations, and adjustments without the need for physical displacement, drastically reducing incident response time.

FTP support enables the secure exchange of data with external servers and remote access to files generated by the controller, such as data logs, essential for audits and post-event analysis. These functionalities enable a more agile, secure, and efficient operational model, supporting remote predictive and corrective maintenance, continuous process optimization, and adhering to the industry's best cybersecurity practices.

Integration between Linux and Docker for edge computing

As an open-source operating system, Linux offers stability, security, and flexibility, fundamental characteristics for optimizing production processes and customizing industrial applications. At Altus, our in-house software team's complete mastery of this system maximize these advantages. This translates into real-time processing, application virtualization and the ability to manipulate large volumes of data directly on the CPU. Moreover, the native presence of a firewall in the system enhances cybersecurityprotecting the control network against unauthorized access and incorporating advanced protection features.

Further expanding these possibilities, integration with Docker transforms the way applications are developed and managed. Docker, based on container technology, allows software to be executed in isolated environments. With this, it is possible to containerize diverse applications such as data analysis models, artificial intelligence algorithms, machine-learning solutions, and execute them directly on the PLC, without dependency conflicts and with high efficiency.

This represents a paradigm shift: the PLC transcends its traditional control function to become a rugged edge computing platformreducing latency and dependence on network bandwidth, optimizing real-time decision-making. All this integration enhances control capabilities for the edge computing architecture in industry, allowing companies to implement distributed intelligence and innovate with new functionalities directly in the control layer.

Learn more: 5 real applications of Docker + Edge Computing

Simplified diagnostics and agile maintenance

The One Touch Diag (OTD) is a feature that allows the user to check diagnostic information of any system module directly on the CPU's graphical display, with just one touch on the diagnostic button. In conjunction, the Electronic Tag on Display (ETD) enables checking the tag and description of any I/O point or module directly on the display, without the need for external tools or supervisory software. OTD and ETD are direct responses to one of the biggest challenges in industrial maintenance: quick and precise fault identification. By providing information without the need for laptops, software, or printed manuals, these functionalities eliminate steps and dependencies, reducing the mean time to repair, a critical factor for the good availability of an industrial plant.

Integrated knowledge management

NX CPUs have the ability to store the complete project documentation in their internal memory. This is a valuable feature not only for backup purposes, but also mainly for maintenance, as the complete and updated project information is kept in a single, secure location, always accessible. This knowledge management strategy ensures the maintenance team has immediate access to the latest electrical schematics, process diagrams, programming logics, and operation manuals,even in locations without network connectivity. This minimizes dependence on external systems and reduces the probability of errors caused by outdated information, enhancing asset management by integrating knowledge with the hardware.

Redundancy that ensures high operational availability

- CPU Redundancy: the NX series features redundant CPUs, designed for applications that cannot stop, ensuring control continuity even if a CPU fails.

- Ethernet Redundancy: the NX3008 has native support for ring closure without the need for external accessories, and can be configured to integrate ring management directly into the CPU.

- PROFIBUS-DP Redundancy: the series also supports PROFIBUS-DP network redundancy, which can be combined, with support for redundant field heads, ensuring that communication with field devices remains uninterrupted.

Confira nossos tutorais sobre redundância na CPU NX3030

Modular architecture with Nexto NJ

Part of our Nexto System, the NJ is a strategic extension of the NX seriesconceived as a versatile and optimized solution for small and medium-size applications. With its compact design, NJ modules maintain the innovative characteristics and the reliability of the entire Nexto System, offering a bridge to advanced automation in segments where the complexity and cost of large-scale solutions could hinder operational innovation.

The modular architecture allows NX CPUs, field heads, and racks to use NJ modules. One of the great benefits of this modularity is the optimization of space in panels, a critical factor for compact applications. The modules are available in 24 Vdc digital I/O, analog voltage and current I/O, and analog temperature input (RTD and TC), in addition to a standardized size of 18 mm, which allows for a high density of I/O points in a reduced physical space. This wide range of modules demonstrates Nexto's ability to meet a wide variety of control needs.

Some modules also have the ability to integrate the HART protocol,enabling advanced bidirectional communication with field instrumentation. With this, it is possible to access detailed diagnostic data from devices, perform remote parameterization of sensors and actuators, and the functionality of using secondary variables directly in the CPU program without the need for its own asset management program.

Applications in high-performance industrial environments

The entire series demonstrates its versatility and ruggedness by adapting to a wide range of applications. Its impact is most notable in sectors that demand the highest levels of performance and reliability, such as:

In the oil and gas sector,the NX series offers solutions for exploration platforms, refineries, terminals, and pipelines. The distributed control capabilities ensure operational efficiency, enhance safety in hazardous environments, and enable predictive maintenance to minimize downtime and risks. In this sector, which operates under extremely challenging conditions and strong regulatory pressure, Nexto features are directly applicable, ensuring the safety of teams, production continuity, and environmental compliance.

In agribusiness, automation with the NX series optimizes the workflow from cultivation and harvesting to transport and storage. The series' ability to integrate data collection from sensors with machine and process control allows for optimized allocation of inputs (water, fertilizers, and pesticides), minimizing losses and improving harvest quality, enabling higher levels of productivity and sustainability.

In the sanitation sector, the series plays a fundamental role in monitoring and controlling complex processes (water levels, turbidity, chemical dosing, pump and valve operation), and ensuring the quality of treated water and the effectiveness of effluent treatment. The remote monitoring and control capability is vital for the distributed infrastructure of treatment plants and distribution networks.

In the transportation sector, the NX series is applied in material handling control and logistical systems. The direct benefits include the systematic reduction of errors and absolute and standardized control of logistical processes, resulting in greater agility throughout the supply chain. NX equipment can enable precise control of conveyors, automated sorting systems, automated guided vehicles, and storage and retrieval systems.

No In the steelmaking sector,the series allows for more precise control from melting to rolling, resulting in more consistent and high-quality products and contributing to the reduction of raw material and energy waste, improving worker safety by automating dangerous and repetitive tasks, and facilitating maintenance to reduce downtime.

In the sugar and ethanol industry,the NX series optimizes the digitalization of plant processes, being able to manage complex operations in closed pipelines and supply the need for remote measurements. This automation contributes to compliance with ESG practices, which are increasingly important for the sector.

And beyond the mentioned sectors, the NX series also stands out in other sectors such as pulp and paper,optimizing production processes for greater efficiency; textilewhere automation streamlines tasks and allows for more flexible and personalized production lines; and in the glass sector,where automation is crucial for handling fragile materials, high temperatures, and the need for millimeter precision.

We invite you to explore more about the capabilities of these equipment by contacting our specialists to discuss your automation demands through the form below!