The era of Industry 4.0 has imposed a scenario where efficiency and productivity depend on increasingly interconnected and highly adaptable automation systems.

The demand for solutions that integrate the production environment with digital data requires controllers that act as intelligence centers, capable of managing this data in real time and enabling new levels of operational efficiency, which drives the search for technologies that offer not only control, but also high connectivity and advanced security.

No crescimento desse cenário, a Altus, com mais de quatro décadas de experiência no mercado de automação, desenvolveu a linha Nexto XP como uma resposta estratégica a esses desafios, introduzindo controladores compactos e poderosos com E/S integradas como uma nova porta de entrada para a indústria de automação inteligentehelping to enable all types of businesses in the IoT universe.

In this article, we will explore the differentiators of the XP series, presenting the main functionalities of the products and how they can boost your business's efficiency.

Versatility and high precision with a compact size

The Nexto XP series was developed to offer rugged and precise control in operations, with a high-speed 32-bit ARM processor and high processing capacity for the execution of complex control logic, advanced calculations, and an agile acquisition of real-time data, ensuring the necessary performance for demands where speed and precision are critical factors.

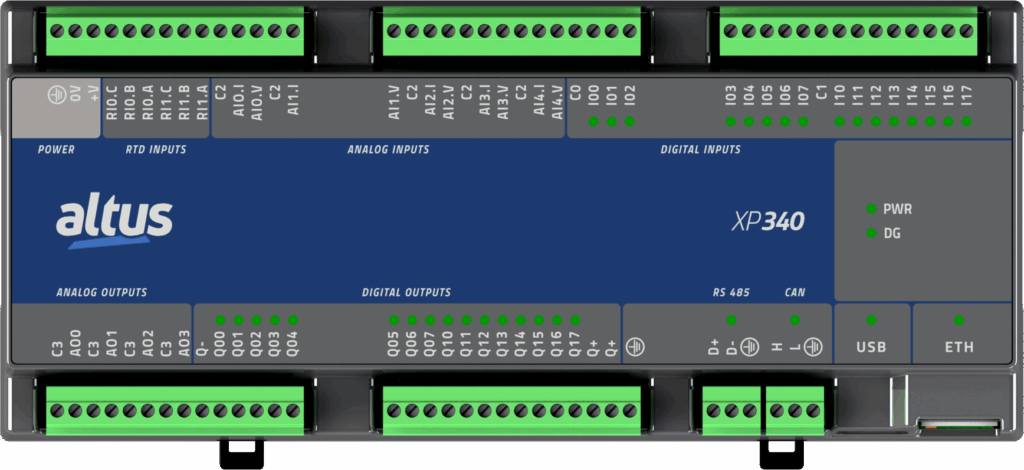

With a compact design, XP controllers stand out for the density of integrated input/output points, concentrating up to 48 points in a single PLC. This comprehensive set includes digital and analog inputs and outputs with native support for RTD temperature sensors for applications that require fast control, going against the perception that “compact” implies “limited” in terms of capacity.

And the modules XP101, XP106, XP201, XP600 and XP610 further expand the functionalities of PLCs. Connected by the CANopen protocol, they operate in slave mode and are configured by our software, MasterTool IEC XE, the same one used for all controllers of the Nexto System. Versatile, these modules can be applied in various sectors, such as infrastructure, building automation, water and effluent treatment, the food industry, textile, factory automation, machines, and other OEM solutions, as each model can meet the specific needs of each application.

And beyond these characteristics, the integration between the 32-bit ARM processor, the Real-Time Clock (RTC), and this high density of I/O expansions gives the Nexto XP series an exceptional processing capability, ensuring precision and agility in data acquisition and response. The analog outputs, for example, demonstrate this speed by updating all channels in less than 1 ms.

The Nexto XP series combines precision in variable control with high speed and economy, offering superior performance for machines such as labeling, blow molding, and injection molding machines.Its high processing capacity and I/O density enable faster cycles, greater precision in process regulation, and, as a result, a significant increase in productivity and a reduction in waste. In addition, the execution of complex calculations and advanced control functions further expands the added value of the solution.

The series also stands out for enabling advanced automation even in environments with physical constraints or in projects that previously had to give up on performance due to space or budget limitations. With ability to execute control algorithms and process data in real time at the network edge,Nexto XP products ensure maximum efficiency and process optimization, without sacrificing available volume or generating additional costs.

Flexibility with a proprietary expansion series

The Nexto XP series was designed with flexibility in mind, allowing for its scalability through expansion modules that connect efficiently via a CANopen interface, instead of a proprietary bus, and are configurable via MasterTool IEC, ensuring a simplified and agile integration, as mentioned previously.

These modules were developed to complement not only the Nexto XP series, but also to work in conjunction with the portfolio of the Nexto Systemsharing the same technology and engineering environment. This standardization offers a strategic advantage by providing a scalable solution capable of serving everything from more compact projects to large industrial applications, while reinforcing the design openness and the interoperability of the entire series.

The XP series of expansion modules is diverse to meet various I/O needs:

- XP101: has 16 digital input points (24 Vdc).

- XP106: combines 8 digital input points (24 Vdc) with 6 digital relay output points.

- XP201: provides 16 transistor digital output points (24 Vdc).

- XP600: adds 4 analog voltage/current input channels.

- XP610: offers 4 analog voltage/current output channels.

And beyond this modular scalability, the line also offers controller models with more specific functionalities for application optimization:

- – XP340 (WebServer and IEC 60870-5-104): the XP340 model stands out for its WebServer (Webvisu) support, which allows for the creation of supervision and monitoring screens directly on the controller, eliminating the need for external SCADA software. These screens are embedded in the PLC's memory and can be accessed via a web browser from any device (computer, tablet, smartphone), resulting in a considerable reduction in cost and project complexity. And it also supports the IEC 60870-5-104 protocol, a standard for supervision and data acquisition with event logging.

- – XP350 (Motion Control): the XP350 model is optimized for motion control applications, offering support for PLCopen Motion Control Part 1 function blocks. This allows for single-axis command and multi-axis synchronization, in addition to features like electronic gearing (CAMe) and a special editor for planning movements (CAM), using the EtherCAT and CANopen protocols for high precision.

Integration with a wide range of industrial ecosystems

The Nexto XP series was designed with a rugged set of communication interfaces, including Ethernet, RS-485, CAN and USBthat ensure agile and flexible integration in different industrial scenarios. Its multi-protocol capability, one of the series' great differentiators, guarantees interoperability with connectivity.

The wide range of protocols supported by the series, such as OPC UA and MQTT, positions it as a strategic link in the convergence between Operational Technology (OT) and Information Technology (IT). This integration, essential and at the same time challenging for various segments, overcomes barriers of proprietary and isolated OT systems that made data exchange with IT solutions, such as ERPs and cloud platforms, difficult and expensive.

By offering native support for various protocols, the Nexto XP PLCs act as edge devices collecting data from industrial machines and sensors — via field and industrial Ethernet protocols, such as Modbus, EtherCAT, CANopen, EtherNet/IP and PROFINET — and transfers it securely and efficiently to systems or cloud environments, using OPC UA and MQTT.

This native support for MQTT and connectivity with major cloud platforms, such as Microsoft Azure, IBM Cloud, Google One, Amazon AWS and Alibaba Cloud and one more USB interface that allows for connection with 3G/4G modems and Wi-Fi adapters, enables data transmission from remote and geographically dispersed units without the need for a dedicated wired network infrastructure. The VPN/Firewall support provides connectivity flexibility for rugged solutions and practical challenges of IoT implementation in distributed and remote environments, where wired network infrastructure may be unfeasible.

Check out our playlist of tutorials with MQTT applications

Simultaneously, these resources address the growing concerns about cybersecurity. The deployment of traditional wired network infrastructure (such as Ethernet and fiber optic cables) in dispersed assets, like remote pumping stations, agricultural sites, or distant power facilities, is often unfeasible and operationally complex. Wireless connectivity is able to reduce this barrier, allowing for the collection of data from isolated points.

The strategic combination of flexible wireless connectivity (via USB adapters) and rugged, multi-layered cybersecurity features (integrated Firewall, VPN) means that Nexto XP equipment can enable distributed and scalable solutions.This allows companies to extend their digital transformation efforts to remote assets, facilitating data collection for operational insights, diagnostics, and greater control, while ensuring the integrity, confidentiality, and availability for these critical infrastructures.

This capability is instrumental in enabling more advanced applications, such as predictive maintenance, big data analysis, machine learning, and remote monitoring, which enables faster and more precise decisions, in addition to optimizing the performance of the entire production network, an essential step for accelerating digital transformation in industries.

The brain of the operation: MasterTool IEC XE

Based on the CODESYS platform, a global standard in automation, the MasterTool offers a complete and intuitive environment for all stages of a project's lifecycle: programming, debugging, configuration, and application simulation. The software provides a comprehensive optimization of the project lifecycle:

- – Intuitive programming: MasterTool IEC XE supports five programming languages of the IEC 61131-3 standard, including Structured Text, Ladder Diagram, Sequential Function Chart, Function Block Diagram, and Continuous Function Chart. Its interface is user-friendly, object-oriented, with graphical programming and advanced editing features that integrate the application, field networks, and process networks into a single interface.

- – Debugging and real-time monitoring: facilitates the identification and correction of errors with the simultaneous visualization of registers and the program's source code. “Trace” functions allow for graphical monitoring of internal variables directly on the controller, eliminating the need for external supervisory systems for debugging.

- – Simulation: includes a powerful tool that operates in offline mode, allowing users to evaluate and test algorithms and programming logic before they go into operation. This capability anticipates errors during the planning stages and allows for testing changes beforehand without interfering with the real system.

- – Online changes: allows for the editing and loading of the application while the system is in operation, minimizing downtime and speeding up commissioning and maintenance.

- – Integrated configuration: enables the definition of all configuration parameters for field networks and standard communication protocols in a single environment, allowing for the import/export and reuse of configurations in other projects.

- – More advanced functions: supports the development of sophisticated functions, such as process variable manipulation, recipe management, mathematical functions, PID control blocks, and timers. In addition, it features support for the MSSQL CLIENT functional block for direct access to Microsoft databases, allowing for integration with data management systems.

Check out more than 150 tutorials to program and enable the possibilities with the XP series

Ruggedness designed to last

To ensure the integrity and longevity of Nexto XP products, the printed circuit boards undergo a conformal coating process (tropicalization). During this process, a thin layer of non-conductive material is applied to protect the electronic components against aggressive elements common in industrial environments, such as corrosion, extreme temperatures, sea air, and humidity. This insulating coating provides continuous and fault-free operations even in the most adverse conditions..

The equipment supports vibrations (7 mm amplitude from 5 to 8.4 Hz; 2 G from 8.4 to 500 Hz) and shocks (15 G for 11 ms, with 6 shocks on each of the 3 axes). They operate in a wide temperature range (-20 to 60°C, or 0 to 60°C for UL/cUL) and support relative humidity from 5% to 96% without condensation. They also have rugged isolation (1500 Vdc/1 minute) between different interfaces, protecting against electrical interference and ensuring signal integrity.

This strategic combination of physical safety certifications (UL/cUL for hazardous locations, DNV-GL for extreme environments) and ruggedness (conformal coating, resistance to vibration/shock) with cybersecurity features (Firewall, VPN) demonstrates the products' high safety levels to minimize operational risks at all levels.

Enable greater performance in your business

The Nexto XP series is the right step for anyone who wants to enable their business to operate in the IoT universe, connecting processes, machines, and people in a smart, secure, and future-ready ecosystem, transforming data into strategic decisions and boosting their competitiveness.

If your company is looking to increase efficiency, reduce costs, and accelerate digital transformation, talk to our specialists through the form below and discover how the Nexto XP series can be your next step toward Industry 4.0!