Altus, with its solid trajectory of more than four decades in industrial automation, will participate in the 32nd FIEE – International Fair of the Electrical, Electronics, Energy, Automation, and Connectivity Industries,the only business fair in Brazil that presents the most varied solutions and trends in electrical and electronic installations for all types of industries.

This year's edition will take place from September 9 to 12, at the São Paulo Expo, and Altus will be present at the booth within the collective space of ABINEE/RS.There, our team of specialists will be available to present complete solution architectures for supervision, control, and protection for hydroelectric plants, as well as for other critical applications in energy infrastructure.

FIEE 2025 is an opportunity for professionals, engineers, and managers to explore the technologies that are redefining the standards of efficiency that their most demanding applications require.

Therefore, we invite you to visit booth J50 to learn about our product lines and understand how automation translates into operational and competitive advantages for your business.

Check out details of the products that will be at our booth

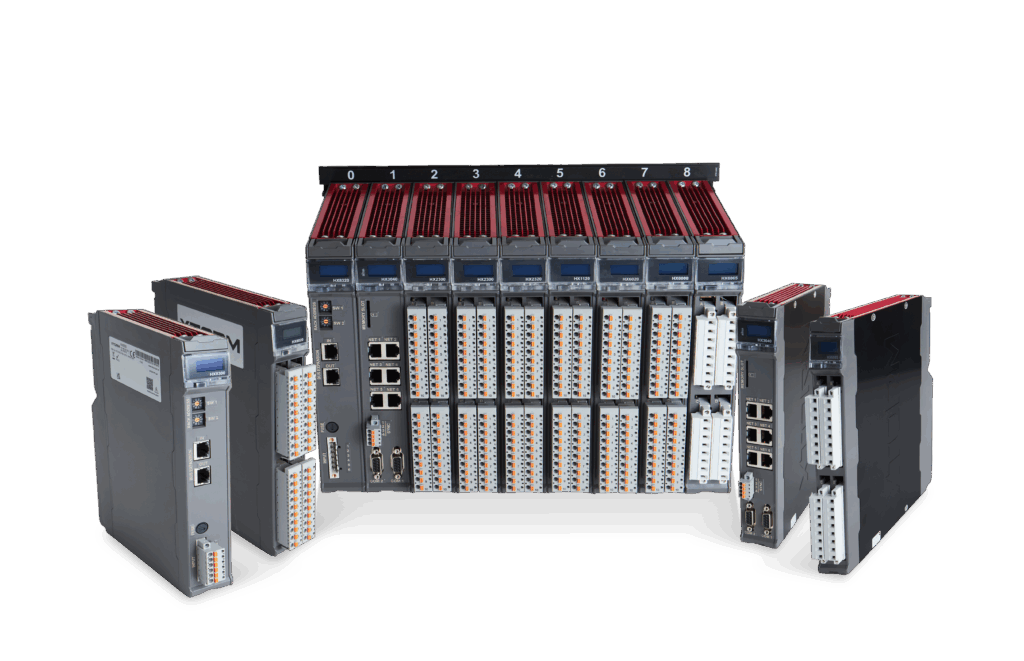

Xtorm RTUs for HPP automation

The RTUs of the HX (Xtorm) line are Altus's cutting-edge solution for the energy generation, transmission, and distribution segment, and they stand out for the 2500 Vac electrical isolation directly on the digital outputs, a differentiator that eliminates the need for intermediate relays for protection, making them ideal for high-level applications in HPPs and substations.

The architecture supports hot-standby CPU redundancy,in which a main processing unit (active) and a backup one (standby) work in sync to ensure process continuity. If the active CPU fails, the backup unit automatically takes control.

Complementing this, the power supply redundancy ensures that, in case one of them fails, the second one takes over the power supply without interruptions. And the modules can be hot-swapped to provide continuous maintenance without the need to shut down the system.

The series is compatible with essential electrical sector protocols, such as IEC 61850, DNP3, and IEC 60870-5-104. These standards allow for efficient and secure communication with control centers and intelligent electronic devices. The RTUs also feature a time synchronization resource via an IRIG-B port, ensuring millisecond precision for event logging, which is critical for fault analysis and diagnostics. In addition, the rugged design, which includes high immunity to electromagnetic interference and insulating coating (conformal coating), ensures that the equipment operates reliably even in hostile environments.

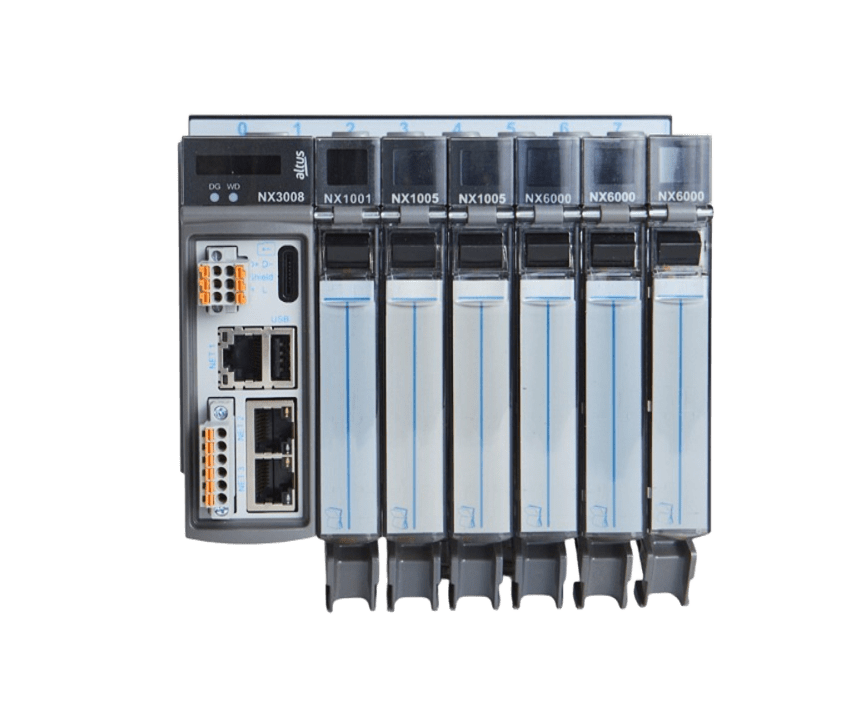

NX3008: a global CPU for your business

With 3 Ethernet interfaces and a vast list of communication protocols, such as OPC UA, MQTT, EtherCAT, EtherNet/IP, and PROFINET,the NX3008 is the ideal solution for systems that require extensive connectivity. And the security features, such as firewall and VPN support, ensure the protection of the control network and secure remote access.

Its advanced software and cybersecurity functionalities, in conjunction with the ability to process complex arithmetic calculations, advanced control functions, and more than 1,000 PID loops in as fast as 2 milliseconds.

And beyond high-speed processing, ample data storage capacity, bus expansion for up to 24 racks, and advanced real-time diagnostics, the most rugged Nexto NX processing unit is a complete solution for delivering performance, connectivity, and versatility for the most varied demands of smart automation.

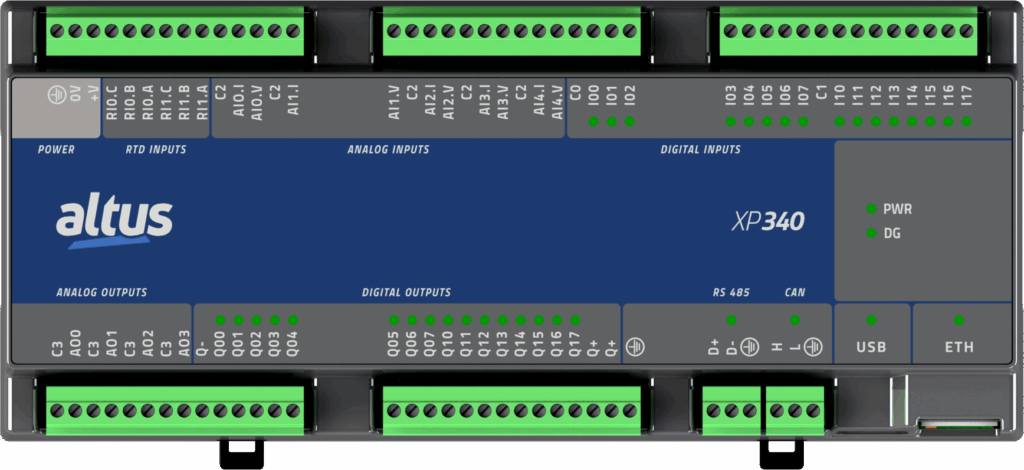

XP340: speed and high performance for operations

The XP340 is a compact, high-density I/O solution, designed for stand-alone and distributed applications. Its DIN rail mounting design makes it ideal for limited spaces in control panels. The XP340 stands out in the electrical sector for its native support for the IEC 60870-5-104 protocol, an essential standard for communication with energy control centers via a TCP/IP network.

A high-value-added functionality of the XP340 is the integrated webserverThis feature allows for the creation of supervision and monitoring screens directly in the controller's memory, accessible by any browser on computers, tablets, or smartphones. This eliminates the need for dedicated SCADA software in many smaller applications, resulting in a significant reduction in costs and project simplification. The ability to have the control logic and the supervision interface in a single programming environment (MasterTool IEC XE) is a strategic advantage for project optimization.

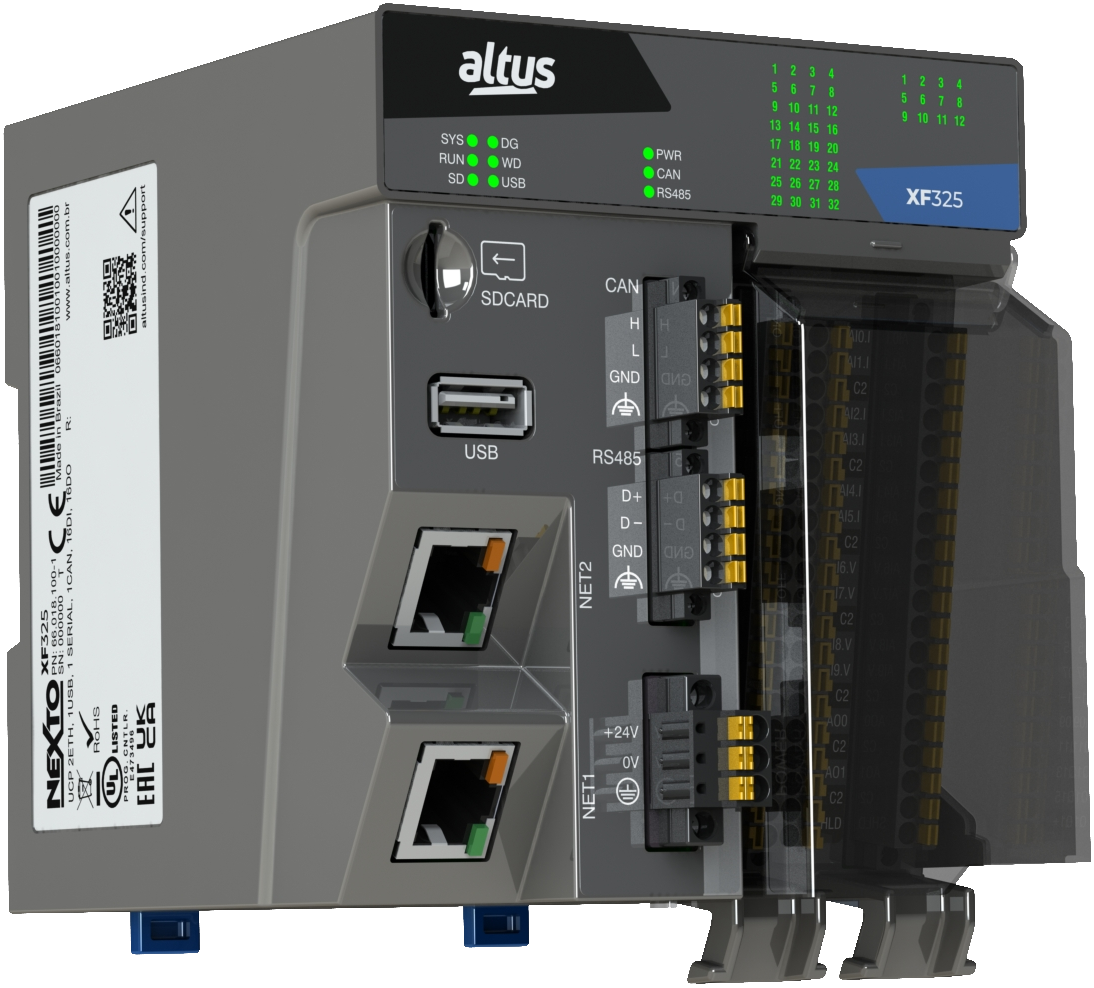

Nexto XF: Advanced connectivity, smart performance

The new XF series as a whole stands out for its high density of embedded I/O modules, offering up to 44 integrated points in a single controller between digital and analog inputs and outputs, depending on the chosen model(consult our sales team to check product availability).

For applications that demand more I/O points, the system can be easily expanded through expansion modules coupled to the high-speed bus. The flexibility extends even further with the ability to increase I/O points through remote (distributed) devices that communicate via protocols such as CANopen, EtherNet/IP, PROFINET, EtherCAT and MODBUS. This combination of high processing capacity, low energy consumption, compact format, and extensive I/O modularity, added to the rugged expansion options, makes the Nexto XF series a highly versatile solution.

At our booth, you will be able to see the first prototype developed for this new series of PLCs.

NL717: connectivity and telemetry for IoT

The NL717 is the datalogger of the Nexto System developed specifically for telemetry and remote monitoring. Its main characteristic is its integrated LoRa radiothat allows for long-range communication. The radio operates on the LoRaWAN standard, ensuring reliable connectivity to distances of 3 to 4 km in urban areas and 10 to 12 km in rural areas.This range allows the NL717 to efficiently collect and transmit data from field sensors.

It also has high-precision analog inputs with 24-bit resolution and support for the SDI-12 protocol for communication with hydrological and environmental sensors. The ability to operate with an extended power supply range (10 to 30 Vdc) makes it compatible with alternative energy sources, such as solar panels.

Gateway LoRa GW700: the bridge to your remote network

The GW700 is a complement to the NL717, acting as the central point of the infrastructure for LoRa communication. Its function is to receive data sent via radio by the NL717 and other End Nodes and inject it into the plant's Ethernet network, serving as a bridge between the long-distance wireless network and the wired network.

The GW700 was built for outdoor environments, with an enclosure of IP67 protection that makes it immune to dust and water immersion, ensuring reliable operation in severe conditions. The gateway operates on the frequencies of 915 to 928MHz and offers network security through encryption and security keys.Its configuration and diagnosis are done through an integrated web server, facilitating the installation.

Speed and economy for applications with the X2 and P2 HMIs

The X2 HMIs provide a local and intuitive point of interaction for the control and visualization of processes. The terminals' design is rugged and features a cast aluminum mechanical structure that combines high quality with lightness. The front is completely flat, which facilitates cleaning and prevents dust accumulation.

The 7-inch widescreen display with TFT technology offers 30% more usable area and allows for brightness adjustment and high contrast. The resistive touchscreen has a lifespan of 1 million touches,ensuring durability and reliability.

The X2 HMIs are programmed using the iX Developer software, which offers advanced and intuitive graphical tools for creating high-functionality interfaces. The HMIs also support remote access via VNC, allowing supervision and operation to occur securely from any point on the network.

Complementing the X2 series, the P2 series of HMIs also presents itself as a rugged and reliable solution for industrial operation and visualization applications. Designed with high-performance hardware and a modern design, the flexibility of the P2 series is evidenced by the availability of models with and without an Ethernet port, in addition to supporting serial and USB communication interfaces. The P2 models can also be combined with a CPU on the rear,creating a compact and integrated PLC+HMI solution, being ideal for small and medium-sized automation applications. Both the X2 and P2 families support remote access via VNC, allowing remote control and monitoring.

At our booth, in addition to this diverse mix of products, we will have a specialized technical-commercial team ready to show you how the technology of our products can optimize your business's efficiency. This team's expertise combined with our portfolio provides our clients with customized and highly advanced solutions.

The future of the industry is smart and increasingly connected.

Altus offers the necessary technology to prepare your company for this future.