Exploration of the oceans has always been linked to the evolution of technology. From the great voyages of discovery to tankers and offshore platforms, the sea has established itself as a place full of challenges. Behind its beauty, there are severe conditions for any technological infrastructure. Constant vibrations from propulsion systems, intense thermal variations, the continuous presence of salt spray, and the requirement for uninterrupted operation make the naval environment a testing ground for automation systems.

In this scenario, operational reliability is an essential necessity. The failure of an onboard controller can mean not only financial losses but also jeopardize the safety of the crew and the environment. It is with the objective of offering this high level of security that Altus has consolidated its presence in the maritime market by achieving the inclusion of the latest equipment from the Nexto NX series in the DNV Type Approval.

This certification covers high-technology products: the NX3035 redundant CPU and the NX1006, NX2025, NX6014, and NX6134 modules, reaffirming our commitment to meeting the highest global quality standards with technology developed in Brazil. Learn more about the certified products and how they can add value to your operations in this article.

A global seal of trust: understanding DNV certification

The DNV certification is considered the “gold standard” for the naval and offshore sector. It is a rigorous validation attesting that electronic equipment is capable of operating reliably under the adverse conditions of a vessel. The DNV-CG-0339 standard, which governs this process, requires exhaustive testing for electromagnetic compatibility (EMC), mechanical resistance, and climatic durability.

The issuance of the Type Approval is the result of a meticulous engineering process and rigorous quality control conducted by our team. By choosing DNV-certified products, companies have the assurance of equipping their vessels with technologies that reduce the risk of unplanned downtime and comply with the requirements of international safety legislation.

For Altus, this milestone reinforces our position as a strategic partner in providing solutions for cargo ships, cruise liners, FPSOs, and high-complexity offshore platforms.

Get to know the Nexto NX series in detail: Nexto NX: connectivity and scalability for high performance automation

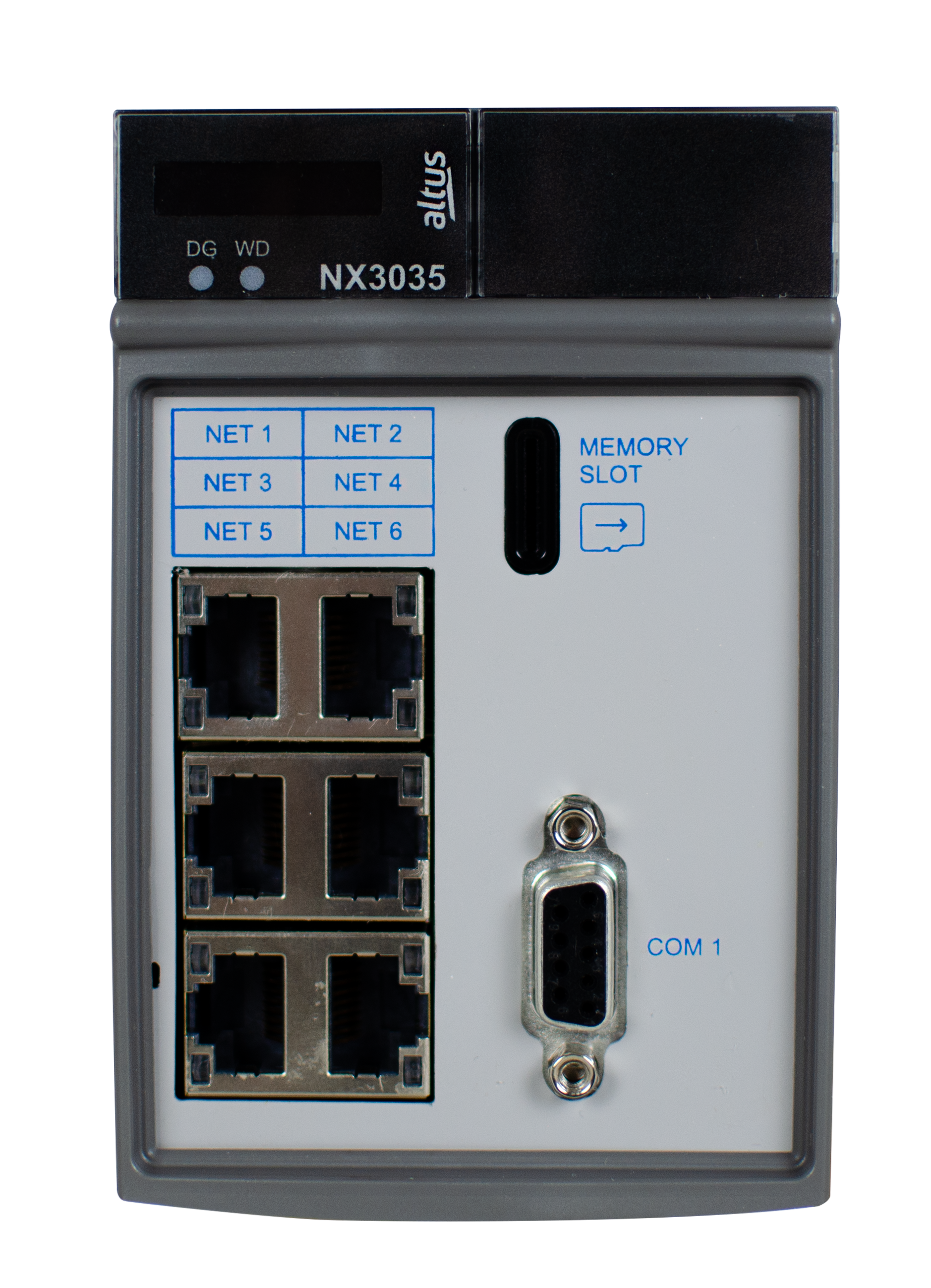

NX3035: redundant controller for maximum reliability in naval systems

Designed for critical naval environments, NX3035 combines fast processing with hot-standby redundancy, ensuring continuous operation even under adverse conditions. With a 64-bit architecture based on high-performance ARM technology, it is capable of managing everything from simple machine systems to complex distributed onboard architectures.

The main differentiator of NX3035 in naval applications is its native support for hot-standby redundancy.In critical systems, such as dynamic positioning or main engine control, the failure of a single controller cannot result in the shutdown of the entire process.

The Altus architecture enables the use of two NX3035 controllers installed in separate racks(half-clusters) operating in total synchrony. Should the active CPU identify an internal failure or loss of power, control is automatically transferred to the standby CPU. This process, known as switch-over, happens in a few milliseconds, ensuring that actuators and valves maintain the control signal and that the operation continues without any disturbance.

The NX3035 also features two SFP interfaces for optical modules, dedicated exclusively to redundancy synchronization. This allows the use of fiber optic transceivers to interconnect the two controllers at distances of up to 10 kilometers, ensuring electrical isolation and allowing the installation of CPUs in distinct compartments, which increases system protection against localized events, such as fires.

The elimination of the use of batteries for clock and memory maintenance is an important feature for the naval sector. The technology Battery Free Operation (BFO) reduces the need for manual interventions to replace consumable components, which is especially relevant for vessels that remain at sea for long periods with limited access to replacement parts.

Here are some of the main features of this controller:

| Feature | NX3035 |

| Processing capacity | 64-bit high-speed ARM |

| Retentive/persistent memory | 8 MB (Battery-free) |

| Ethernet interfaces | 6 10/100/1000 Mbps ports |

| Redundancy channels | 2 SFP Ports (1.25 Gbps) |

| Real Time Clock (RTC) | 1 ms resolution with SNTP synchronization |

| Main protocols | Modbus, OPC UA, PROFINET, EtherCAT, MQTT |

Learn more: NX3035: high-performance redundancy for critical process control

Uninterrupted surveillance with the NX1006 and NX2025 digital modules

Onboard safety is made up of several layers, and monitoring the physical integrity of automation equipment is one of the most essential. The NX1006 and NX2025 modules from the Nexto NX series were developed to ensure that the control system has, at all times, the certainty that field devices and their wiring are in proper operating conditions, offering immediate diagnostics for fault prevention.

NX1006: smart input monitoring for F&G (Fire & Gas) systems

In Fire and Gas (F&G) detection systems, rapid response depends on sensors distributed throughout the vessel. The NX1006 module offers 8 monitored digital sink inputs, capable of identifying not only the sensor's binary state (on/off) but also physical faults in the connection circuit, ensuring greater system reliability.

Through current monitoring techniques, the NX1006 detects conditions such as broken lines or short circuits. Thus, if a cable is damaged by mechanical vibration or corrosion, the CPU receives an immediate diagnostic, allowing the maintenance team to act preventively before a real emergency occurs, enabling preventive maintenance before a critical situation arises.

NX2025: safe control and advanced diagnostics of actuators

Complementing the safety layers, the NX2025 module manages the digital outputs that trigger sirens, fire-fighting pumps, and emergency valves. It features 8 monitored source-type transistor outputs, capable of identifying faults such as open load (absence of load) or overcurrent conditions.

In naval applications, the NX2025 module ensures that devices such as fire-fighting systems are electrically connected and ready to operate. Should a valve coil fail or a power cable come loose, the module generates an immediate diagnostic on the CPU display via the One Touch Diag function,alerting the crew to the safety system failure.

See the main features of these modules:

| Specification | NX1006 (input module) | NX2025 (output module) |

| Signal type | Sink (Monitored) | Source (Monitored) |

Diagnostics | Broken line / Short-circuit | Open load / Short-circuit / Overload |

| Galvanic isolation | 1500 Vdc for 1 minute | 1500 Vdc for 1 minute |

| Internal protections | Surge and Resettable Fuse | Surge and polarity reversal |

| Tropicalization | Circuit coating (Conformal Coating) | Circuit coating (Conformal Coating) |

The 1500 Vdc galvanic isolation present in these modules is fundamental for the system's electrical stability on vessels. In marine environments, voltage spikes and electromagnetic noise generated by large induction motors are common and can affect the controllers' logic. This isolation ensures greater electrical immunity, preserving the safe and reliable operation of the system.

Learn more: Nexto NX Modules: I/O solutions to transform your operation from control to predictive intelligence

NX6014 and NX6134: elevating instrumentation performance with HART intelligence

Precision in reading analog variables, such as tank levels, oil pressure, and exhaust temperature, is what differentiates an efficient operation from a scenario with a risk of mechanical failure. With the NX6014 and NX6134 modules, Altus brings HART technology to the marine environment, ensuring greater reliability and intelligence in onboard automation systems, now reinforced by DNV certification.

The HART protocol is widely used in the maritime and oil and gas sectors because it allows digital communication to be superimposed on the traditional 4–20 mA analog signal. As a result, a single pair of wires can transmit not only the process variable, such as tank pressure, but also additional information, such as sensor diagnostic data, manufacturer identification, calibration range, and maintenance alerts. The NX6014 and NX6134 modules integrate this capability directly into the Nexto PLC.

- – NX6014: it features 8 high-resolution (24-bit) analog inputs, ensuring extremely precise readings from multivariable instruments.

- – NX6134: offers 4 16-bit analog outputs with HART support, ideal for controlling intelligent valve positioners that require continuous feedback on their physical position and operational status.

On board a ship, many field instruments are installed in hard-to-reach areas or potentially hazardous environments. The use of Nexto HART modules allows technicians to perform the configuration and calibration of these devices remotely,via the PLC's Ethernet network and asset management tools compatible with DTM technology.

This feature reduces the need for physical movement on board, increases crew safety, and enables a predictive maintenance strategy.Thus, it is possible to monitor signs of degradation in sensors, such as residue buildup in ballast level gauges, and schedule interventions before the reading becomes critical to the vessel's stability.

See the main features of these HART modules:

Specification | NX6014 (analog input) | NX6134 (analog output) |

| Converter resolution | 24 bits (guaranteed monotonicity) | 16 bits (high stability) |

| HART Channels | 8 configurable channels | 4 configurable channels |

| Enhanced precision in electric current | ±0.1% of full scale | ±0.1% of full scale |

| Update time | 10 ms to 200 ms (depending on filters) | 1.25 ms |

| Electrical protections | Surges and permanent voltage up to 30 Vdc | Voltage surges |

| Tropicalization | Circuit coating (Conformal Coating) | Circuit coating (Conformal Coating) |

Learn more: HART over PROFIBUS and PROFINET applications with Nexto PLCs

Innovative design and simplified maintenance at sea

The Nexto NX series, was developed not only to offer robustness, but also to be intuitive and practical for those who operate the system daily. The innovations incorporated into the products ensure that onboard maintenance is faster, safer, and less prone to errors — a strategic differentiator when repair time directly impacts the ship's operation and logistics. Among these features, the following stand out:

- – One Touch Diag (OTD) and Electronic Tag on Display (ETD): With this function, a single touch on the module's diagnostic button is enough for all error information to be displayed on the CPU's graphic display. Complementing this agility, the Electronic Tag on Display enables the identification (TAG) and description of each input or output point to be viewed directly on the display. This eliminates reliance on printed manuals and ensures the technician knows exactly which sensor or actuator is being analyzed.

- - Easy Plug System (EPS) and Hot Swapping: the Easy Plug System function of the NX series uses a terminal block connection method that ensures greater mechanical fixation and facilitates disconnection without the need for special tools. In practice, this means faster commissioning and simpler, safer maintenance. Furthermore, all the certified equipment mentioned throughout this article (NX3035, NX1006, NX2025, NX6014, and NX6134) supportHot Swapping, allowing a defective module to be replaced without turning off the CPU or interrupting the control of other vessel processes. In redundant systems, this functionality enables availability levels of up to 99.99%.

- – Conformal Coating: All Nexto NX equipment submitted for DNV certification features electronic circuit protection coating (Conformal Coating). This treatment creates a physical barrier against humidity, dust, and aggressive chemical agents,ensuring that the internal circuits remain protected from conditions typical of a vessel.

Achieving DNV certification for these Nexto NX series products is confirmation that Altus's Brazilian engineering has reached one of the highest levels of reliability on the global stage. Whether through the protection offered by conformal coating, the predictive intelligence made possible by the HART protocol, or the safety guaranteed by hot-standby redundancy, the Nexto NX series consolidates itself as the ideal choice for mission-critical applications. With DNV certification, Altus reaffirms its commitment to boosting productivity and protecting what is most valuable in the oceans: life and the future.

Discover how the Nexto NX series can optimize instrumentation and increase the reliability of your naval operation by contacting us through the form.