Altus officially introduces the Nexto XF series to the market, the latest launch within the Nexto family of Programmable Logic Controllers (PLCs).

The industry 4.0 era has been defined by interconnectivity, real-time data processing, and the ability to adapt to dynamic environments. In this scenario, PLCs have evolved from mere control devices into true network intelligence centers to enhance the connectivity, performance, and flexibility demanded by data-driven industries.

The Nexto System, recognized for its excellence and high performance, was developed to meet these demands, offering PLCs that interact with smart devices, advanced systems, and cloud-based solutions, creating a fully connected environment. With cutting-edge technology, this equipment provides reliability and fast response, incorporating edge-computing platforms and facilitating agile data processing for real-time decision-making.

It is within this ecosystem of innovation that Altus is pleased to present the Nexto XF series, the new member of its 5th generation of programmable controllers.

This launch marks a new chapter in Altus's trajectory: this series arrives as a strategic solution that further expands the possibilities within the ecosystem of resources specially designed for applications requiring high performance and integration of the Nexto System, elevating the productive and technological potential of industrial processes to an even higher level.

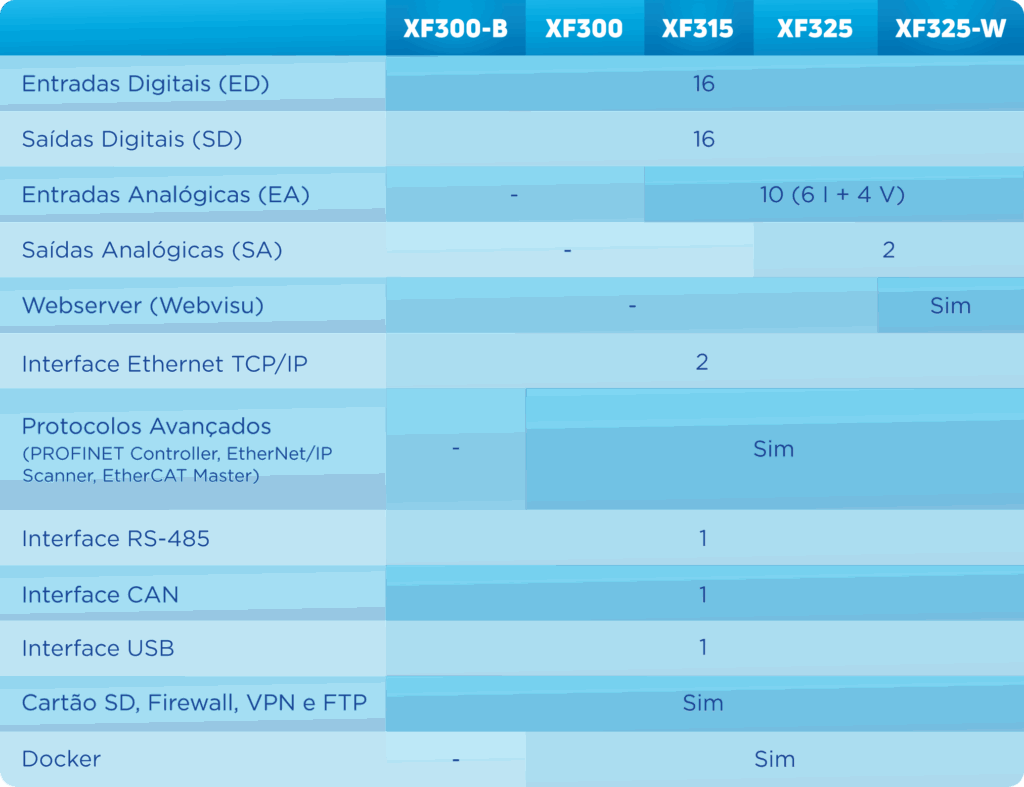

Nexto XF is a series of modular CPUs, which will feature 4 models, designed to meet the demands of machine manufacturing industries and all types of automated processes, capable of acting as both independent controllers in edge computing applications and as remote processors in distributed systems, complementing the already consolidated Nexto portfolio for small and medium-size applications. Its flexibility to integrate into projects of different sizes, using the same technology and engineering environment, represents a strategic advantage for engineers and integrators to standardize their applications across a much wider range of project scales, simplifying development, optimizing operational costs with training and maintenance, and further reinforcing the Nexto System's proposal of versatility.

With the slogan "Advanced connectivity, smart performance", the Nexto XF series arrives combining rugged hardware with advanced software features. In this article, we will show how this solution can open new possibilities in the field of automation.

Compact power for smart control

At the core of Nexto XF CPUs is a 64-bit dual-core ARM processor, operating at 1 GHz, which offers a high-performance architecture capable of transforming computational capacity into results in process control. This processing power enables the execution of 1,000 PID loops and complex calculations in less than 2 milliseconds, ensuring extremely fast responses and precise control, which are essential requirements for dynamic and high-speed applications. The system's efficiency is also evident in metrics such as the execution of 1,000 contacts in just 2.1 microseconds. More than numbers, this data demonstrates the real capability of the series to handle the increasing demands of complex processes and machine cycles, offering the speed and precision required for modern automation.

The design of the CPUs was conceived and optimized for embedded applications and environments with limited physical space. Its compact and modern form factor, ideal for DIN rail mounting, facilitates installation in small cabinets and machines. Direct 24 Vdc power supply makes this integration even simpler, while its low power dissipation contributes to the energy efficiency of the system as a whole, reducing the need for additional cooling and increasing equipment reliability and lifespan.

The XF series, in general, also stands out for its high density of embedded I/O modules, offering up to 44 embedded points in a single controller, including digital and analog inputs and outputs, depending on the model chosen(consult our sales team to check product availability).

For applications demanding more I/O points, the system can be easily expanded through expansion modules coupled to the high-speed bus. Flexibility extends even further with the ability to increase I/O points through remote (distributed) devices, which communicate via protocols such as CANopen, EtherNet/IP, PROFINET, EtherCAT, and MODBUS.

This combination of high processing capability, low energy consumption, compact form factor, and extensive I/O modularity, coupled with robust expansion options, makes the Nexto XF series a highly versatile solution. This means the possibility of developing more compact, efficient, and cost-effective applications without compromising performance. In addition, the flexibility to scale the same platform in standalone or distributed projects simplifies both engineering and maintenance, promoting standardization and agility across different application scales.

More connectivity for more integrated industries

Connectivity is the basis for more agile and data-driven processes, and Nexto XF CPUs were designed to act as a robust and versatile communication hub within this scenario. The CPUs feature a wide range of physical interfaces, including two 10/100 Mbps Ethernet ports, one RS-485 serial interface, one CAN port, one USB Host (V2.0), and one interface for a microSD card. This diversity ensures compatibility with different architectures and applications, allowing the CPU to easily integrate into existing or expanding industrial environments.

But what truly expands the communication power of the XF series is its impressive compatibility. The CPUs support a comprehensive set of communication protocols, such as OPC UA, MQTT, EtherNet/IP, PROFINET, EtherCAT, MODBUS (TCP and RTU), CANopen, SAE J1939, FTP, SNMP, OpenVPN, RSTP, and MRP. Protocols like OPC UA and MQTT are especially important for integration with cloud solutions, IIoT applications, and data analysis platforms, ensuring system interoperability, operational security, and standardization in information exchange.

Moreover, beyond wired connectivity, the CPU XF also offers flexibility for remote and distributed applications. The USB Host port allows the connection of devices such as USB-to-serial converters, 3G/4G modems, and Wi-Fi adapters, an essential feature for locations where wired infrastructure is limited, expensive, or nonexistent, such as in mobile assets, field installations, or temporary environments.

By reducing latency and dependence on external connections, the XF series ensures faster responses and greater operational autonomy, which is fundamental to critical operations. With its embedded Webserver, the controllers enable data analysis and the creation of supervision and monitoring screens directly on the equipment itself, using the new MasterTool X that will be launched soon. This feature reduces the need for dedicated HMI panels in various applications, promoting cost savings and greater flexibility of access to system information.

Edge computing and virtualization with the Nexto XF series

Among the most advanced features of the Nexto XF series is the embedded Linux platform, native to its CPUs. This functionality paves the way for the virtualization of Unix applications directly on the controller, allowing the execution of Docker-based solutions, Python scripts, and CODESYS libraries, all operating in an integrated and local manner.

As proof of Altus's commitment to increasingly technological architectures, the CPUs offer memory dedicated exclusively to Docker usage, ensuring performance and stability even in demanding applications.

This new model results in leaner architectures, lower hardware costs, increased security (with data being processed locally), and considerable gains in efficiency. In summary, the Nexto XF series brings not just new PLCs, but rather distributed intelligence platforms, ready to elevate the level of automation and process optimization in the most diverse industrial applications.

Robust security and high reliability with international certifications and extra protection

The Nexto XF series was developed with a comprehensive approach to security and reliability, both cybernetics and physical security. To protect data integrity and allow secure remote access, the controllers feature embedded firewall and VPN support (OpenVPN client/server), in addition to FTP functionality for secure file transfer. These features are fundamental for mitigating risks associated with cyberattacks and ensuring protected communications in connected environments.

In terms of physical protection, the XF CPUs undergo a rigorous tropicalization process, known as conformal coating,which applies a non-conductive protective layer over printed circuit boards. This protection defends components against corrosion, humidity, sea spray, extreme temperature variations, and chemical substances present in challenging industrial environments.

The rugged design of the series goes beyond protection against external agents. Being fanless and battery-free, the equipment eliminates moving parts and components subject to wear, which reduces the need for maintenance, increases its lifespan, and improves system reliability. This ruggedness is reinforced by its wide operating temperature range, from -20°C to 60°C, and by its high resistance to shocks and vibrations, essential characteristics for field applications or harsh environments.

The excellence of Nexto XF is also confirmed by rigorous international certifications. The controllers comply with standards such as IEC 61131-2/3 and hold CE, UKCA, UL, and DNV Type Approval certifications. DNV certification ensures its safe application in maritime and offshore environments, while UL Class 1 Div 2 is essential for areas with explosion risk, such as oil and gas facilities. These credentials reinforce reliability for highly regulated and demanding market niches.

The combination of cybersecurity protection, physical ruggedness, and international compliance ensures reliable operation, even under extreme conditions. This results in less downtime, extended lifespan, and investment protection. For those who cannot risk their operations, the Nexto XF series is the right choice.

We invite you, automation professional, to get to know the first PLC of the series closely starting in the first half of 2026 and discover how this new generation can boost your projects and take your operations to a new level.

For more information and to explore the full potential of the solution, access our exclusive page , check out the official video, and fill out the form so you will not miss the next updates on this launch!