Auren Energy, the third-largest power generator in Brazil, stands out in the Brazilian market for its strategic focus on the investment and development of 100% renewable energy generation. Its operations cover hydroelectric, wind, and solar plants in various regions of Brazil.

The company positions itself as one of the forces in Brazil's energy transition to drive an increasingly sustainable future, and such future demands the modernization of critical infrastructures, such as hydroelectric plants, as smart automation enables efficient maintenance of energy grids to achieve the goals of greater sustainability and the country's energy demand.

However, even forward-thinking companies can face infrastructure challenges.At the Picada hydroelectric plant, Auren faced a critical turning point: the existing automation system, based on an obsolete PLC, was unsupported and nearing the end of its lifespan. This situation did not represent just an isolated technical problem; it was an operational and strategic risk.

Given this, the motivation for seeking a new solution was, therefore, the need for modernization to ensure safety and reliability, investing in technologies that could mitigate these risks and optimize long-term management. In search of a more intuitive, easy-to-program, and, above all, reliable system, Auren found in Altus the ideal partner for this project.

Nexto technology as a solution for obsolescence

Altus was chosen as a partner based on a combination of decisive factors: the presentation of success stories in similar applications, which demonstrated the company's experience in the energy sector and a competitive proposal that not only met all of Auren's technical requirements but also offered superior cost-effectiveness; and, above all, the in-depth technical knowledge, openness, and flexibility of the Altus team, qualities observed and valued since the initial negotiation phases.

The technological solution proposed by our team of specialists was the implementation of Xtorm RTUs, which are part of the Nexto System within the Nexto HX seriessince they are designed for the supervision and control of power generation, transmission, and distribution systems, they stand out for the 2500 Vac electrical isolation directly on the digital outputs, a differentiator that eliminates the need for intermediate relays for protection.

This characteristic simplifies the system's architecture, reduces the risk of failures, decreases the demand for corrective maintenance, and shortens intervention time in the field. The absence of relays generates the following economic gains: fewer components to be acquired, less effort for assembling and wiring, and a reduction of the space occupied in the electrical panel.

Moreover, unlike traditional PLCs, which are more geared toward localized control and centralized applications, RTUs are developed for large areas and remote applications. Their main focus is on supervision, telemetry, and control in power plants and substations, using advanced communication standards such as IEC 61850,, high-speed processing driven by a Linux system, a rugged design for critical environments, as well as redundancy and I/O module features..

This transition from a PLC to an RTU was a strategic move from a localized control to a more distributed architecture, fully adapted to the complex and high-availability requirements of the energy sector, ensuring that the system was not only modernized but also prepared for future demands of the power grid.

RTUs for control and supervision of integrated systems

The modernization implemented by Altus at the Picada HPP covers all the essential equipment for the plant's operation; this includes the management of auxiliary services, the control of the substation, and the automation of the generator unit's startup and shutdown processes.

The comprehensiveness of this control demonstrates that the Altus solution is not a one-off fix for an isolated problem, but rather a technological modernization that integrates and optimizes operations. The project was meticulously designed to be simpler, more intuitive, easier to program, and, consequently, more reliable than the previous system. This emphasis on simplicity and intuitiveness is a vital point for usability and for reducing the learning curve of Auren's maintenance team, minimizing potential operational errors and optimizing long-term efficiency.

The main features of the Nexto HX series show the ability of this equipment to provide ruggedness with high performance:

- – High durability: the design is extremely rugged, enabling operation in harsh environments. The RTUs are resistant to mechanical vibrations, have an extended operating temperature (from -5 to 60°C), and feature high immunity to electrostatic discharge and electromagnetic noise. In addition, the modules feature conformal coating, a thin layer of non-conductive material that protects the electronic circuits against corrosion, sea air, and humidity.

- – High availability: the series offers several redundancy architectures, including redundancy for Central Processing Units (CPUs), Power Supplies, and Network Interfaces (with NIC Teaming support), as well as hot-swapping of modules, enabling the replacement of components without the need to shut down the system.

- – Advanced diagnostics: each module in the HX series has its own diagnostics and multifunctional displays that report its status. Features such as One Touch Diag (OTD) and Electronic Tag on Display (ETD) allow users to check diagnostic information and identify I/O tags directly on the CPU display, even offline.

- – Battery-Free Operation (BFO): the HX series does not require any type of battery for memory maintenance and real-time clock operation. This feature reduces the need for periodic maintenance, showing how this equipment is ideal for operations in remote locations.

- – Multiple Block Storage (MBS) e On Board Full Documentation (OFD): the series’ CPUs have a large memory capacity, supporting various types of variables and logs. And the OFD functionality enables access to the complete project documentation directly on the CPU, facilitating backup and maintenance.

These characteristics not only solve the immediate problem of obsolescence but also enable Auren for an even more proactive and predictive operation. The hot-swapping capability and battery-free operation provide a lower Total Cost of Ownership (TCO) and a higher Return on Investment (ROI) by minimizing interruptions and costs with constant maintenance.

Multi-protocol approach to overcome limitations

The solution is based on an interoperable communication architecture structured for the complexity of a hydroelectric plant. For this reason, the implementation of IEC 104, Modbus, and PTP protocols was essential for the application's success.

The IEC 104 is a protocol for SCADA (Supervisory Control and Data Acquisition) networks in power plants. It enhances interoperability between devices, provides logical access to data, and makes possible the efficient control of existing electrical equipment. Its asynchronous communication capability, where spontaneous events can be sent without a prior request, is an important step for open and smart automation beyond closed proprietary systems.

The Modbus has open source code, enabling flexible communication between various industrial devices, such as sensors and controllers. It operates in both master/slave (Modbus RTU) and client/server (Modbus TCP/IP) architectures, being vital for energy management and the operation of smart grids. Modbus TCP, in particular, offers the advantage of supporting a virtually unlimited number of devices through IP addressing, overcoming the limitations of serial communications..

Finally, PTP, based on the IEEE 1588 standard,ensures time synchronization with microsecond precision. This precision is indispensable for substation protection and automation systems, where the precise time stamping of events is crucial for fault analysis and regulatory compliance. PTP integrates into Ethernet-based systems and offers benefits such as automatic path length compensation and support for redundant time sources, increasing the synchronization's reliability.

The joint implementation of these three protocols by Altus demonstrates the expertise to meet various communication needs within a hydroelectric plant. This multi-protocol approach creates a rugged, highly interconnected, and precise automation ecosystem, enabling continuous flow of data and control in all layers of the plant's operations.

The successful integration with Auren's supervision system

One of the success points of the Altus-Auren project was the fluid integration of the solution with the installation's existing supervision system. This is a platform widely used by Auren's engineering team, which means the team already has familiarity and expertise in its operation, facilitating the transition and adoption of the new system.

Altus ensured that its solution matched perfectly with this infrastructure, protecting Auren's previous investments and ensuring a smooth transition. This compatibility and the ability to work in combination with the client's systems are proof of the flexibility of Altus's engineering team, resulting in a cohesive and adaptable operational environment for the client.

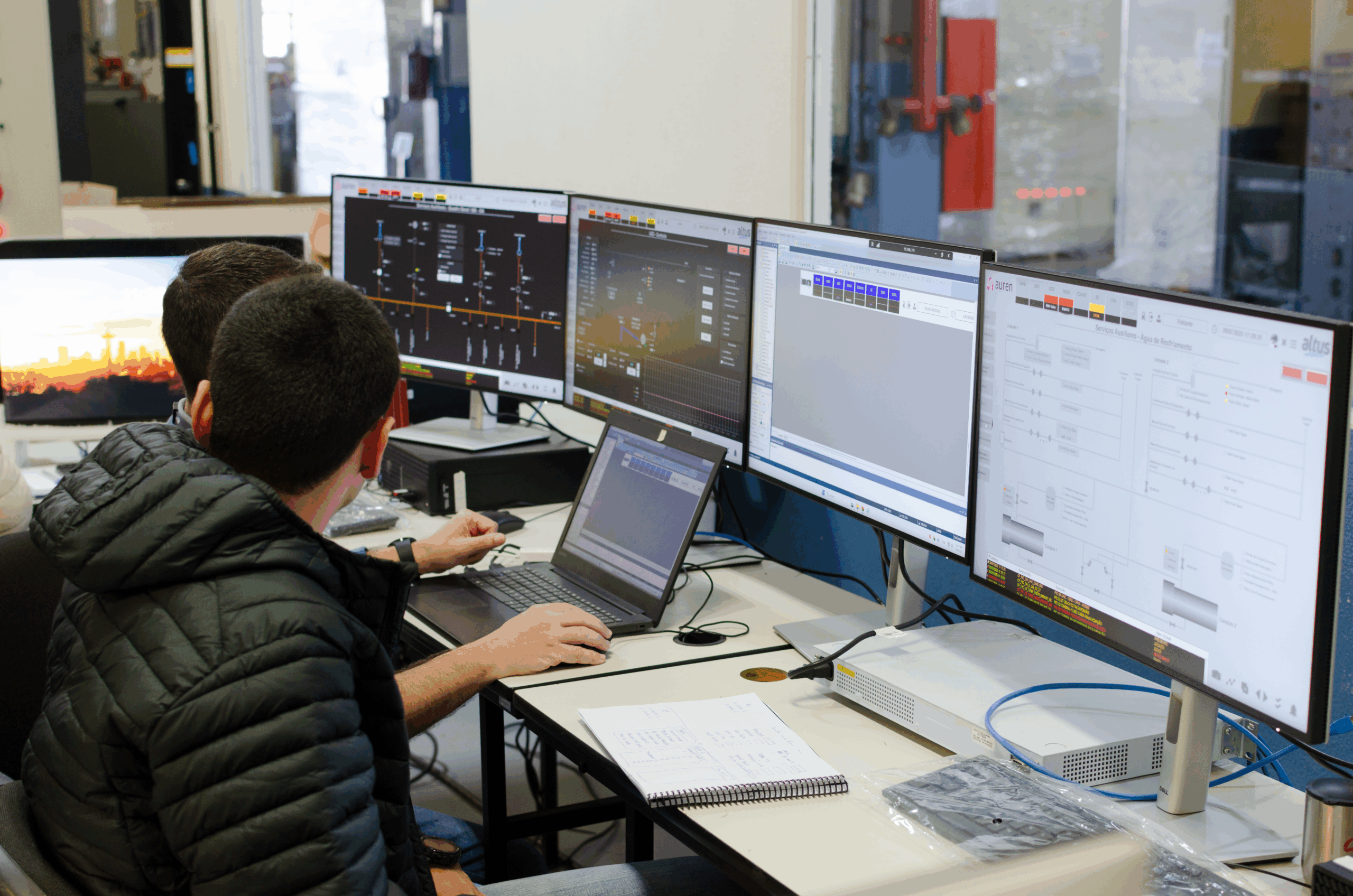

E, In addition, although the Picada hydroelectric plant modernization project is still in the development and testing phase, Auren Energy is already observing significant benefits and promising potential. The search for equipment and technologies for greater reliability in operations is already proving to be fulfilled. There is a clear perception that the Altus solution, together with other project platforms, has the potential to generate substantial gains in productivity, safety, and economy.

Élcio de Oliveira, Supervisor, and Alexandre, Maintenance Technician at Auren, expressed a very positive experience with Altus since the first contact. The interaction with the Altus team, in all spheres—commercial, support, and engineering—was consistently praised. They highlight that the Altus team demonstrates “a lot of knowledge about what is proposed, in addition to great flexibility and receptivity.”

Auren also highlights “the ruggedness, the great finish, and the quality of Altus products, which are perceived as easy and practical to handle, comparable to or even superior to established brands on the market,”as reinforced by supervisor Élcio de Oliveira during the project's FAT period.

The potential of digitalization in the energy sector

The partnership between Altus and Auren in the modernization of the Picada Hydroelectric Plant is a striking example of how cutting-edge technology combined with specialized expertise can redefine operations in the energy sector.

The replacement of an obsolete PLC with RTUs represents a significant leap in reliability, agility, and management capability for Auren. With a rugged architecture, advanced communication features, and smart diagnostics, the solution not only mitigates the risks of obsolescence but also ensures operational continuity, cost optimization, and long-term safety.

This project is consolidated as a benchmark for companies in the sector that face the challenges of aging infrastructure and the urgent need for modernization. It proves the effectiveness of an approach capable of strengthening operational resilience, reducing costs, and boosting efficiency gains.

For companies that want to raise the standards of safety, reliability, and efficiency in their operations, Auren's experience with Altus clearly and validly demonstrates the transformative potential of digitalization in the energy sector.