Between October 14 and 17,Altus has confirmed its presence at Mercopar 2025, the largest industrial business and innovation fair in Latin America.

Held annually in Caxias do Sul, in the Serra Gaúcha region, at the Festa da Uva Exhibition and Event Center, the event is a fundamental stage for companies that, just like Altus, drive digital transformation and the competitiveness of the sector.

Promoted by Sebrae-RS in partnership with the FIERGS System, the 34th edition of Mercopar reaffirms its strengthened focus on connecting companies and generating high-impact business, with a rugged structure of business rounds for large corporations and micro and small equipment (MPEs).

The fair brings together leaders and innovations in the metalworking, information technology, energy, industrial automation, electro-electronic, among various other segments, promising to present new trends.

And on the 17th (Friday), at 6 p.m., on Stage 1, our product specialist, Nícolas Fratti Nunes, will present the lecture "IoT Ready Controllers adding efficiency to the Industry." Nícolas is an electrical engineer and data science specialist, with 20 years of experience in automation, working in the development of solutions for the industry.

During the presentation, Nícolas will mix technical content with real application cases to demonstrate how IoT Ready controllers are fundamental in digital transformation and in creating innovative IoT solutions for the sector.

The lecture will also address how these devices can be key to increasing operational efficiency, both in new architectures and in legacy applications, utilizing the pillars of Industry 4.0 and the new technology available.

Operating for over 40 years in the technology market for the industry, Altus will demonstrate essential equipment and solutions at its booth to meet the demands of the smart industry, in addition to a new item in the portfolio.

The people who visit booth W20 will be able to check out the technology and ruggedness of our main equipment series up close with our specialists, such as:

NX3008: a global CPU for your business

The main attraction we will be bringing will be theNX3008, a high-performance CPU from the Nexto NX series of controllers. With advanced security functionalities, high capacity formodular architectures connected to the NX and NJ modulesand virtualization, it is a complete solution for systems that require extensive connectivity, delivering performance and versatility for the most varied demands.

The most advanced Nexto NX device has 3 Ethernet ports, with one being Gigabit type and two with PROFINET Controller protocol support, which allows the controller to be used in a network with an MRP ring architecture.

Another advanced feature available isits embedded Docker platform.The resource, native to the CPU, makes software virtualization possible. This gives:flexibility and speed to your operations,enabling multiple software processes to run simultaneously within the CPU itself.

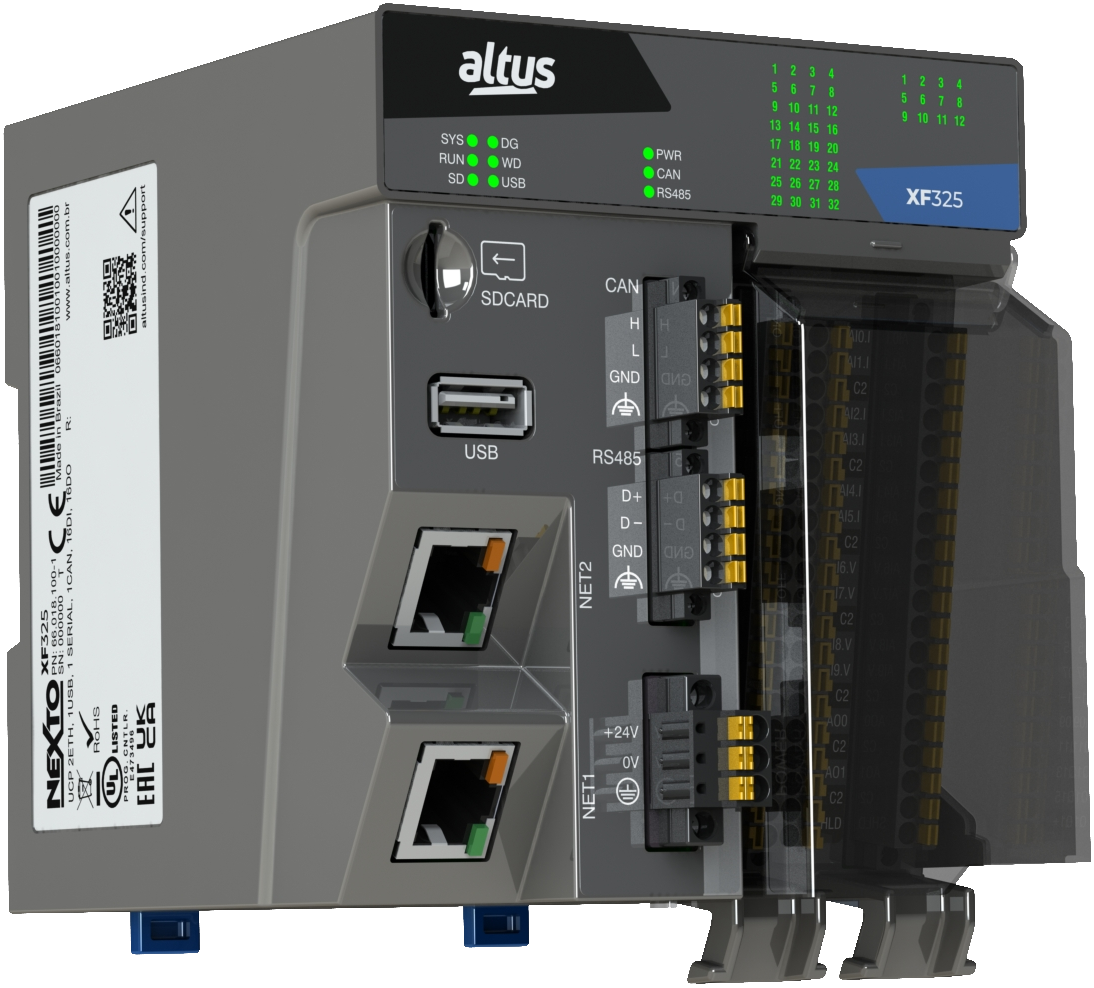

Nexto XF: advanced connectivity, smart performance

The new XF series as a whole stands out for its high density of embedded I/O modules, offering up to 44 integrated points in a single controller between digital and analog inputs and outputs, depending on the chosen model(check with our sales team at the booth to check the availability of the products).

For applications demanding more I/O points, the system can be easily expanded through expansion modules coupled to the high-speed bus. Flexibility extends even further with the ability to increase I/O points through remote (distributed) devices, which communicate via protocols such as CANopen, EtherNet/IP, PROFINET, EtherCAT, and MODBUS.

This combination of high processing capacity, low energy consumption, compact format, and extensive I/O modularity, added to the rugged expansion options, makes the Nexto XF series a highly versatile solution. At our booth, you will be able to see the first prototype developed for this new series of PLCs.

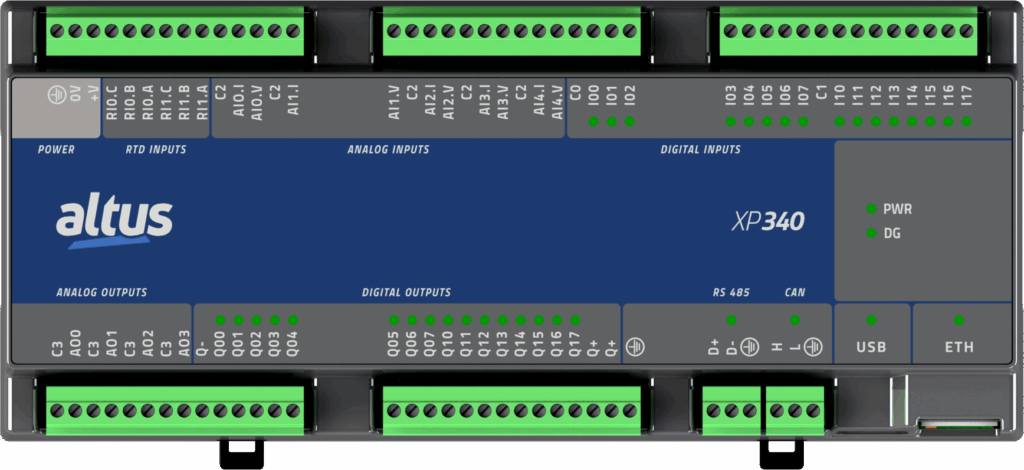

Operate in the IoT universe with the Nexto XP series

The compact Nexto XP PLCs are the ideal solution for meeting the demands of highly connected environments.

With embedded communication interfaces for Ethernet, Serial RS 485, CAN, and USB, these PLCs feature support for a varied list of communication protocols, such as MODBUS TCP and RTU, PROFINET, CANopen, J-1939, IEC 60870-5-104, EtherNet/IP, OPC DA, OPC UA, and MQTT.

The XP340 model is a compact, high-density I/O solution, designed for stand-alone and distributed applications. Its DIN rail mounting design makes it perfect for limited spaces in control panels. The XP340 also features WebServer supporta tool that enables the creation of application supervision and monitoring screens without the need to use a SCADA equipment.

Telemetry and high connectivity with datalogger and LoRa gateway

Created to operate in the monitoring and telemetry processes of the most different areas of the industry, the NL717 datalogger and LoRa Gateway GW700 act in the collection and transmission of data in power generation facilities, hydrological and meteorological stations, among other equipment that require remote data collection.

They use the LoRa communication protocol, a long-range and low-power radio communication technology widely used in various applications in the IoT universe.

Watch the video below to learn about this equipment in detail:

Distributed I/O systems for automation with the G Series

The G Series is an I/O Remote series designed to respond to the demands of the most modern industrial equipment with high technology.

With a flexible, versatile, and smart architecture, the series stands out for its high scalability, ease of maintenance, and compatibility with multiple communication protocols.This set of characteristics makes the G Series remote equipment a highly adaptable solution, capable of operating in complex and varied industrial environments, from sectors such as manufacturing and automotive to critical installations in energy and infrastructure.

Guarantee energy efficiency with the PH3500 multi-meter

The PH3500 multi-meter allows for the remote monitoring of energy consumption in the most diverse applications, such as energy billing in residential and commercial condominiums, electrical equipment in small and large industries, energy generation plants, and other electric power distribution facilities.

With the capacity to be used in voltage, current, frequency, power, energy, and demand measurement applications, this equipment has measurement of voltage and current harmonics up to the 31st order and the capacity to record electrical quantities in general in mass memory.

Veja um exemplo prático de aplicação que comprova o desempenho e a robustez desse equipamento em operação: Mega Goglio otimiza consumo energético com os multimedidores PH3500

Reliability and durability in asynchronous drives across various power ranges

With high performance and low energy consumption, Optidrive frequency inverters present themselves as a solution with excellent cost-benefit for the control of machines and electric motors.

With a wide range of options, the multipurpose drivers of the Optidrive E3, Optidrive ECO, and Optidrive P2 families are suitable for controlling low-power three-phase asynchronous motors.

Features like precise speed control, energy optimization, and sleep/wake functions ensure energy savings for applications like HVAC. Additionally, all products in the Optidrive Eco family feature support for the BACnet and MODBUS communication protocols, which are ideal features to facilitate installation in building equipment.

Speed and economy for applications with the X2 and P2 HMIs

The X2 series HMIs provide a local and intuitive point of interaction for the control and visualization of processes. The terminals' design is rugged and features a cast aluminum mechanical structure that combines high quality with lightness. The front is completely flat, which facilitates cleaning and prevents dust accumulation.

The 7-inch widescreen display with TFT technology offers 30% more usable area and allows for brightness adjustment and high contrast. The resistive touchscreen has a lifespan of 1 million touches,ensuring durability and reliability.

Complementing the X2 series, the P2 series of HMIs also presents itself as a rugged and reliable solution for industrial operation and visualization applications. Designed with high-performance hardware and a modern design, the flexibility of the P2 series is evidenced by the availability of models with and without an Ethernet port, in addition to supporting serial and USB communication interfaces.

The P2 models can also be combined with a CPU on the rear, creating a compact and integrated PLC+HMI solution, making it ideal for small and medium-sized automation applications. Both the X2 and P2 families support remote access via VNC, enabling remote control and monitoring.

Complementing these solutions, we will display at our booth weight transmitters, stepper motors, servo drives and power supplies, demonstrating the versatility and integration of Altus technologies in different applications.

The future of the industry is smart and increasingly connected.

Altus offers the necessary technology to prepare your company for this future.