In addition to counting on the high technology embedded in all our product series, customers who choose Altus solutions also have differentiated service for the development and optimization of their applications. The expertise of our team of specialists, cultivated during our more than 35 years of experience, is the difference that can help you get the most out of your machine, increasing your customers' productivity and strengthening your brand in the market. Recently, the Tronics do Brasil, our Australian client specializing in the manufacture of equipment for packaging and self-adhesive labeling, used this engineering intelligence to launch its new line of double-head labeling machines.

The machines, developed in a co-creation initiative between the client and our team OEM Commercial, are responsible for labeling the manufacturer's lubricating oil bottles Shell. To meet the requirements of the manufacturer, who was looking for a solution to quadruple the performance of their products, our OEM team used technology Nexto Xpress, compact PLC with integrated I/O from the Nexto family. The high speed of the products, which execute 1,000 Boolean instructions every 6 microseconds, 14 times faster than the market average in this category, was essential for the machine to achieve the expected performance. With the new architecture, the labeling machines had a huge increase in speed on their conveyors, going from 10 to 40 meters per minute, which allowed them to reach a production volume of up to 12 thousand bottles per hour with millimeter positioning precision.

Quality and availability are also differentiators of this new line. To avoid production downtime due to adhesive replacement, the labeling machines have two label reels at each end: while one is operating, the other remains on standby waiting to be activated by the PLC – which happens automatically at the end. of each coil. The labeling machines also have a rigorous validation routine that evaluates the units produced and discards those that do not meet the expected quality standard.

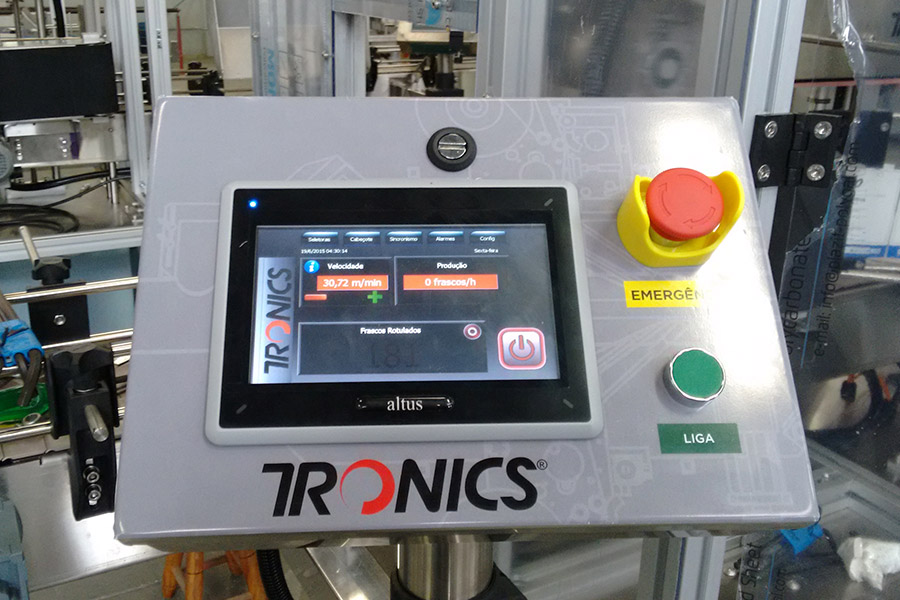

In addition to programmable controllers, the machines also have a HMI for insertion of recipes and supervision of the process, power supply of the Energy Series and our frequency inverters.

Service as a differentiator

In addition to the high technology of the products, Paulo Aranha, the company's Industrial Director, points to the availability of the OEM team, assisting in all stages of the machine development process, as a great asset of Altus. “There are many brands on the market, but what sets Altus apart is its support”, said the Director. He also highlights that the concepts preached by the company, such as using open source in software programming and providing very close support to the customer, were decisive for the initiative to achieve the significant results it achieved.

Tronics launches new line of packing machines with 100% Altus technology

At the end of last year, Tronics had already launched another series of machines that also uses Altus products as a control solution. With the aim of increasing the performance of its customers' production lines, the company developed new automatic boxing machines, which are more agile and efficient. The machines, which are already used in large national industrial companies, operate based on a solution made up entirely of the products we sell.

Meet the Altus OEM team

In addition to the advanced technology embedded in all items in our product families, machine manufacturers who choose Altus solutions also rely on the expertise of specialists from our OEM team. To meet the specific demands of this industry, we have brought together a team of professionals with great technical knowledge and extensive experience in the development, optimization and retrofit of machines. Present from conception to project completion, our OEM team is 100% available to analyze and help with the development of machine software, acting decisively throughout the application's entire life cycle.

We, here at Altus, believe that knowledge is one of the most valuable assets we have and should be shared with customers and other technology enthusiasts. Therefore, all machine software that our team develops uses an open source platform so that the customer can modify it in any way they see fit. We do not retain the intellectual property of the software, it is handed over to the customer so that they have full control over the application.

Do you also have a machine to be renovated or a project that needs help getting off the ground? Click here and talk to our experts!