Industrial automation, often viewed as a universe of imported black boxes and indecipherable lines of code on a screen, gained a new dimension for some of our clients.

On November 11th, the prize winners with the golden ticket from the Fantastic PLC Factory campaign,coming from different regions of the country, had the opportunity to walk the factory floor of our headquarters in São Leopoldo (RS): the heart of Altus technology.

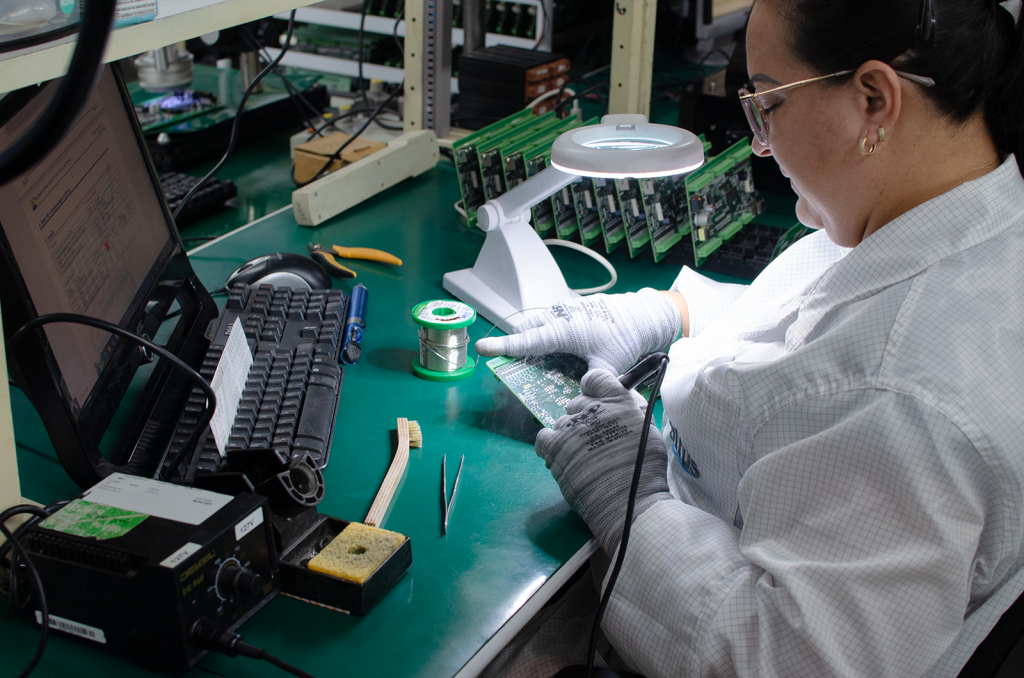

Throughout the visit, the guests were able to see each stage of the process up close: from the anti-static boxes full of electronic components to the millimetric precision of the machines, operated by our team of specialists, passing through the constant rhythm of burn-in tests, which consist of an electrical and thermal stress test to identify and accelerate early failures, in addition to the functional tests of the equipment.

We showed that cutting-edge technology, capable of controlling large critical equipment, is not imported. It is created, developed, and manufactured on Brazilian soil. It is inside this factory that the technology is born that moves about 15% of Brazil's electric power and enables the extraction of 35% of the Pre-salt production,consolidating Altus as one of the protagonists of national industrial automation.

In a global scenario marked by fragilities in supply chains and increasingly sophisticated cyber threats, having complete mastery of the value chain, from the controller's design to the SCADA supervision software, is a differentiator that ensures technological sovereignty and operational resilience.

During the visit, the award-winning clients had the opportunity to closely follow the manufacturing process of the equipment that make up our portfolio.

Were present:

- – Daniel Costandrade and Gabriel Tintori, representing the company Matisa;

- – Manasses Mendes, representing the company MBO Automation;

- – Douglas Caetano, representing the company Volmaker;

- – João Finkler, representing the company Equilati.

Some of these clients won their "golden tickets" during the launch of our new Nexto XF series PLC at FISPAL 2025. Now, by visiting our factory, they had the opportunity to closely follow the first boards of the equipment coming directly off the production line.

When technology is born at home: the pioneering spirit of Rio Grande do Sul that became a global reference

Our history began in 1982, when Altus was born from a postgraduate course at the Federal University of Rio Grande do Sul (UFRGS). This emergence in an academic environment shaped the company's DNA, establishing our foundations in scientific excellence, applied research, and the relentless pursuit of innovation.

And although our strength is undeniable in the national market, where the goal is to be a great reference in technology, Altus's performance goes beyond borders.

We maintain a commercial presence and strategic partnerships in various countries in Europe, Asia, Africa, and the Americas, including Germany, Sweden, Chile, and South Korea. These international research and development alliances, such as those maintained with CODESYS (Germany) and Beijer Electronics (Sweden), reflect Altus's technological solidity and prove that the innovation created in Brazil is in full dialogue with the global automation ecosystem.

"It's great to have the opportunity to visit the Altus headquarters, precisely because of the similarity I see in the situation where a Brazilian company has enough potential and technology to compete with a foreign company, right? Or companies from outside the country, right? So, I feel more hopeful about the technological future of Brazil." Said the client Daniel Costandrade, representative of the company Matisa.

"And one of the characteristics that gives us confidence to continue on our journey is precisely being able to count on the technological security that this partner brings to our company at a business level. It is what gives us the reliability to be spreading Matiza equipment worldwide." He added.

The strategic advantage of verticalized manufacturing

The ability to manufacture automation technology on national territory is the central pillar of Altus's value proposition. Our industrial operations are concentrated in two strategic units in Rio Grande do Sul: the headquarters in São Leopoldo and the branch in Sapucaia do Sul with 100% Brazilian engineering.

The Product Factory in São Leopoldo is the facility responsible for electronic assembly, both surface mount (SMT) and thru-hole (PTH), and for the mechanical complementation and functional tests of the equipment.

The capacity is impressive: the factory can assemble 96,000 components per hour,using high-precision inspection in its process to guarantee the quality of each electronic board. Furthermore, our production adheres to the RoHS directive (Restriction of Hazardous Substances), ensuring that national technology is aligned with the most rigorous global standards.

Complementing this capacity, the Panel Factory in Sapucaia do Sul offers a infrastructure of 3,500 square meters, dedicated to the production and integration of automation panels and power, and with dedicated rooms for conducting Factory Acceptance Tests (FAT).

This control over the final integration of the panels, carried out internally, minimizes risks in the field for large-scale and critical operation projects, such as those carried out on Oil and Gas platforms or electrical substations.

"Matiza has been in the market for 66 years, and certainly one of the main reasons for working all this time, staying aligned with the national market, and always exporting the best products, is having quality suppliers. Not only suppliers that guarantee the quality of the products but also ones that help us continue on this path, assisting both the national market and the international market, strengthening our entire industry and our country as a whole." Commented Gabriel Tintori, representative of the company Matisa during the visit.

R&D and the Altus ecosystem

Product development of world-class at Altus is sustained by continuous investment in Research and Development (R&D). Our multidisciplinary team acts in all stages of the creation process, from hardware design and layout to debugging and final validation of tests, ensuring technical excellence and reliability.

The connection with the academic environment, present since the company's founding at UFRGS, remains alive and strategic. We maintain partnerships with universities and technology institutes throughout the country, such as UFRGS, UNISINOS, FURG, UFRN, and the SENAI Institute, strengthening the bridge between science and industry.

This synergy between research and practice keeps Altus at the forefront of innovation in industrial automation, ensuring that every new equipment incorporates the latest trends and the fundamental principles of Industry 4.0.

“It is a differentiator for any professional in the area to see how the creation of the PLC works, from the beginning of the board until the final equipment is boxed and delivered to each one of us. And the importance of a national PLC company, with the quality that Altus has, is surprising in the market.” Commented Douglas Caetano, representative of the company Volmaker during the visit.

The Nexto System: a Brazilian answer to Industry 4.0

The ultimate expression of this continuous commitment to innovation is the Nexto System, our ecosystem of Programmable Logic Controllers (PLCs) developed to meet the demands of industrial IoT and data-driven applications. The Nexto System brings together high performance, advanced cybersecurity, and broad connectivity with scalability, which are fundamental pillars for Industry 4.0 industrial architectures and for operations that require real-time decision-making.

The architecture of the Nexto controllers was designed to support high-criticality applications, incorporating 32- and 64-bit RISC PowerPC and ARM processors, capable of executing more than 145 thousand instructions per millisecond or up to 500 PID loops/ms, delivering high processing capacity with low power consumption.

Furthermore, the platform offers scalability and versatility. The Nexto XP line, for example, features compact PLCs, ideal for small machines and processes, offering high I/O density (up to 43 points in a single product) and IoT-Ready features, such as an embedded Webserver for creating supervision screens without the need for SCADA software. And the programming of the entire system is done using MasterTool, an integrated environment based on CODESYS technology.

This integrated ecosystem ensures that the entire technological chain, from field devices to supervision, operates with security, availability, and performance. The result is an infrastructure that is continuously updated and adheres to the demands of the modern operational environment, aligned with the best practices and standards.

"The entire process with total quality control, that was very impressive. And seeing that everything is manufactured here at the headquarters in Brazil. That is very important. So, as certified integrators, Altus has been a very strong partner. Regarding deadlines, regarding quality, the support is also very important. When we need it, if we have any doubts, we have nearby support. And it has been very fruitful." Highlighted Manasses Mendes, representative of the company MBO Automação.

We are driven by challenges for the future of automation

Altus' journey, built over more than 40 years, is marked by pioneering spirit that evolved into a reference position in the industry.

Since our origin centered on research and development, we felt that we made an essential strategic choice: maintaining 100% national manufacturing. This decision consolidates our commitment to a clear vision: to offer solutions that boost innovation, productivity, and competitiveness for the market.

The Nexto System is the materialization of this strategy. It proves that technological sovereignty is not just an aspirational purpose, but a competitive advantage. In a connected and dynamic global scenario, fully controlling the automation architecture, with advanced cybersecurity and embedded IoT protocols, ensures the robustness, security, and agility necessary to thrive in Industry 4.0.

More than providing technology, we are strategic partners in the most complex industrial operations in Brazil and the world, ensuring continuity, evolution, and total technological dominance. Our trajectory reflects that of a country that reinvents itself, innovates, and grows driven by great challenges, transforming knowledge into value and progress for the entire industry.