Altus' continued investments in research and development provide the design of high-tech equipment, solutions that adhere to the reality of the international industry and are capable of meeting the most varied demands from different segments. This innovative streak is part of the company's DNA, an intrinsic characteristic in each of the product lines launched throughout its almost 40 years of history.

Altus' continued investments in research and development provide the design of high-tech equipment, solutions that adhere to the reality of the international industry and are capable of meeting the most varied demands from different segments. This innovative streak is part of the company's DNA, an intrinsic characteristic in each of the product lines launched throughout its almost 40 years of history.

After launching the XP340, PLC with WebServer support, and adding new functionalities for the CAN interface of Xpress solution, the Nexto family of programmable controllers now gains a new feature. By updating your controller's firmware to the latest version and the MasterTool IEC XE programming software to version 3.20, all your Nexto Series products will now support the MQTT protocol. The new feature further increases the connectivity of Altus technology and brings your business closer to the reality of Industry 4.0.

A PLC made for the market

The first drafts of what would become the Nexto Xpress family were drawn up in December 2017, through an analysis of the global automation scenario at the time. However, the history of the CLP began long before that date. The genesis of the equipment is intertwined with the emergence of the company itself, since the concept that guided the entire product development trajectory is one of Altus' main values: Customer Focus! Created to meet the demands of the machine and small process market, the controller was designed based on the industry's needs, a 100% customer-driven product.

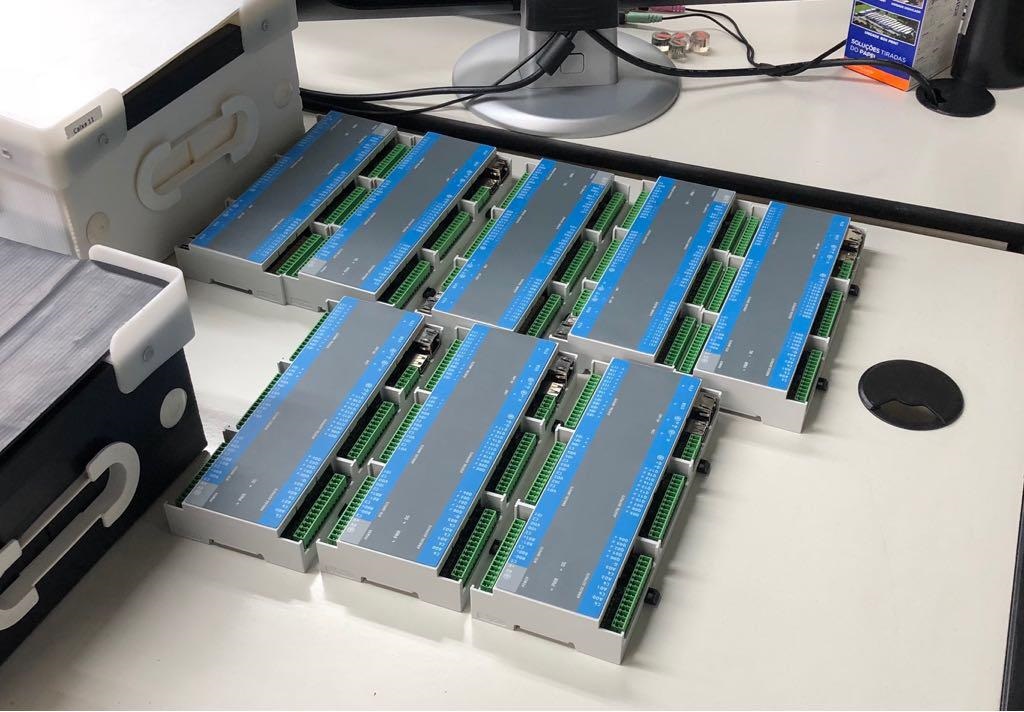

Primeiros modelos para teste do CLP Nexto Xpress

In addition to being highly responsive to market needs, the products in the Xpress family were also designed to meet the demands of another important aspect that was gaining strength and prominence at the time: technologies from Fourth Industrial Revolution. With advanced processing and multiple connectivity features, the family's PLCs can be used in systems linked to practically all pillars of Industry 4.0. The resources embedded in Nexto com.br/post/399/o-que-e-edge-computing-e-como-ele-reduz-o-atraso-de-informacoes-3f-09" target="_blank" style="background-color: rgb(255, 255, 255);" rel="noopener nofollow">Edge Computing, Cloud Computing, Big Data and Data Analysis, IT segments increasingly explored in automation systems.

Processo de testes do CLP Nexto Xpress

Processos de gravação das placas e de injeção da mecânica

Nexto Xpress, the all-in-one PLC from Altus

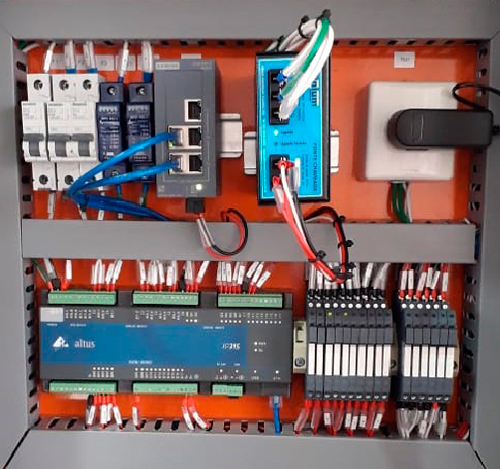

Compact and multi-protocol, the Xpress controller was developed to be a true all-in-one PLC. Manufactured with just one circuit board and a multi-task processor with several embedded resources, the product facilitates the industrialization process and can be used in applications with different purposes, from self-service machines and small building automation to distributed systems in large industries. The fact that the family has conformal coating is also different for a small controller like the Xpress. In the process, a thin layer of non-conductive material is applied to the product plate to protect against corrosion, extreme temperatures, salt spray, humidity, among other factors.

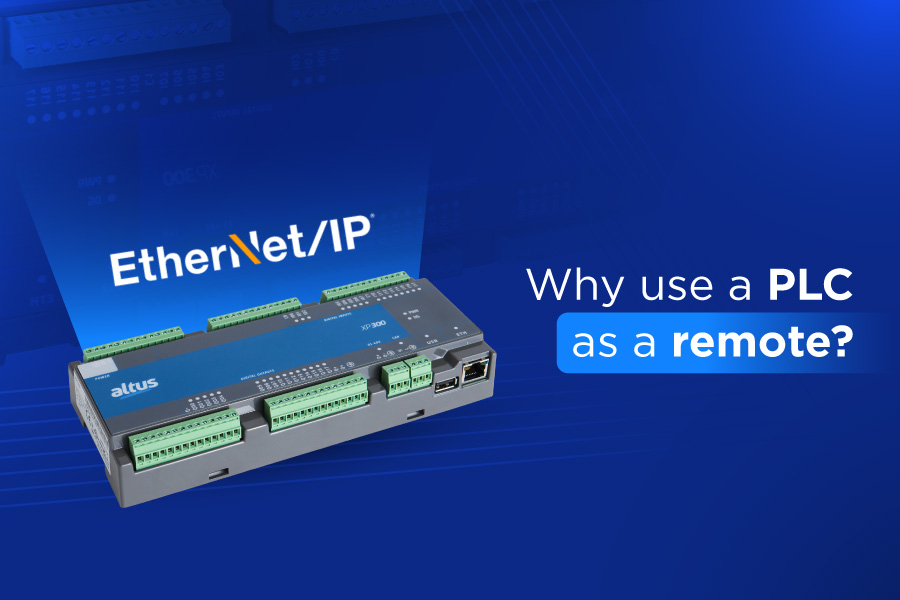

With built-in Ethernet, Serial RS 485, CAN and USB communication interfaces, Xpress products are capable of supporting a wide variety of communication protocols. Today, all models in the line support MODBUS TCP and RTU, CANopen and low level, IEC 60870-5-104, EtherNet/IP Scanner, OPC DA, OPC UA and MQTT standards. This variety of communication possibilities allows Altus' compact PLCs to interact with the most varied devices and intelligent resources found in the industry, from machines and PLCs from different suppliers to WiFi dongles, storages and external ERP systems .

These characteristics mean that the CLP can be used in the most varied industrial environments, such as in applications in the Sanitation and Energy. Over the last few years, Xpress controllers have been applied in the most different applications, such as in water and sewage treatment from CAGEPA and SABESP, as well as in the energy efficiency developed by SEER. In both cases, the high connectivity rate of Altus products was the determining factor in the success of the project.

These characteristics mean that the CLP can be used in the most varied industrial environments, such as in applications in the Sanitation and Energy. Over the last few years, Xpress controllers have been applied in the most different applications, such as in water and sewage treatment from CAGEPA and SABESP, as well as in the energy efficiency developed by SEER. In both cases, the high connectivity rate of Altus products was the determining factor in the success of the project.

To add even more versatility to the systems in which they are used, the family's products also have features that enable them to work in both Cloud Computing and Edge Computing applications. Nexto Xpress PLCs have a native ability to communicate directly with the most relevant cloud hosting services on the market, such as Microsoft Azure, IBM Cloud, Google One and Amazon AWS.

An example of where these resources are widely used are teaching solutions developed for use in technical laboratories at various educational institutions. Recently, PLC technology was used to assemble the Industry 4.0 Training and Development Center of SENAI Minas Gerais, an enterprise to promote the 4.0 journey in industry national. The equipment is also used to technical training of students and young professionals in other SENAI units and in different universities and technical schools throughout Brazil.

To complete, the model XP340 also supports WebServer, a tool that allows the creation of supervision and application monitoring screens without the need to use a SCADA system.

High speed for multi-purpose machines

With compact design (212.5 x 90.1 x 32, 2 mm) and 24 Vdc power supply, the Xpress solution is ideal for the onboard control of small machines and applications. Its 32-bit ARM processor, combined with the real-time clock (RTC) and the high density of multi-purpose digital and analog I/O points (voltage, current and temperature) give the solution a high processing capacity, precision and agilityin data acquisition. These characteristics make the equipment the perfect solution to provide more speed and economy in the control of the most varied machines on the market, such as labeling machines, blowers, washers, injectors, baggers, grinders, presses, among others.

With compact design (212.5 x 90.1 x 32, 2 mm) and 24 Vdc power supply, the Xpress solution is ideal for the onboard control of small machines and applications. Its 32-bit ARM processor, combined with the real-time clock (RTC) and the high density of multi-purpose digital and analog I/O points (voltage, current and temperature) give the solution a high processing capacity, precision and agilityin data acquisition. These characteristics make the equipment the perfect solution to provide more speed and economy in the control of the most varied machines on the market, such as labeling machines, blowers, washers, injectors, baggers, grinders, presses, among others.

Recently, Xpress products were used in the modernization of machines for filling yogurt and dairy drinks from Josmaq, where the architecture applied to the machine has the XP300 as the centerpiece of the control system. Family equipment also appears as a central piece of the control of the Odeme Dental Research thermocycling machine. Developed to carry out scientific research in the field of dentistry, the equipment acts on the accelerated aging process of composite resins and other dental materials through thermal shocks, using a PLC XP315.

Another highlight for this market is the cost of implementing Xpress products. All models in the family require low engineering HH for configuration and deliver high performance for signal reading, resulting in high performance and low cost applications, an ideal scenario for machine manufacturers.

A product made for the international market

In addition to having all the qualifications to be applied to the most varied demands of the Brazilian industry, the Nexto Xpress CLP is fully compliant with the requirements and standardizations of the international market. The line's products were designed to follow the Ecodesign requirements of the RoHS directive, which prohibits the use of certain dangerous substances in the equipment manufacturing process, from its simplest inputs to transport packaging. These characteristics, combined with other precepts, also make the Xpress family compliant with the CE marking, which allows it to be sold in the European bloc.

In addition to these two brands, guarantees of reliability in the global electronics market, Xpress controllers also have UL and CUL certifications. Issued by Underwriters Laboratories, the certifications are a mandatory requirement for exporting products to the United States and Canada, which allows Altus to explore both territories in the northern hemisphere and reinforces the concept of the Nexto Series as a world-class product. Furthermore, to give the line more coverage, the Xpress PLCs will also have the DNV-GL seal, a requirement in some countries for the use of controllers in marine applications, such as control systems on yachts, cruises, ships cargo ships and oil and gas production platform. The certification process has already started with the Det Norske Veritas laboratory and should be completed by the end of 2021.

As it is a product with the highest embedded technology and adheres to all these important certifications, we can say that Nexto Xpress is a PLC with a vocation to be an international star. This aptitude for more versatile projects has already caught the attention of the global market, which has demanded more and more of the product, increasing the scope of Altus equipment.

Today, products from the Xpress family are present on each of the planet's five inhabited continents through the most different applications. Among the main countries where Altus technology is present are Germany, India, Turkey, Italy, Sweden, United Arab Emirates, South Africa, Morocco, Canada, Netherlands, Taiwan, Australia, Norway, China, United Kingdom, United States, among others.

There are many territories conquered by Nexto Xpress programmable controllers in these first three years of the solution's existence. Like their predecessors, our compact PLCs also receive occasional upgrades to add new features and continue to meet the demands of the international industry. This process of constant improvement is part of Altus' DNA, which encourages global technological development, and creates a link between this generation of products and the PLCs that we are designing for the future!