Altus is implementing a new positioning and naming strategy for its main products families, reflecting a careful evolution and a keen eye on market trends. In recent months, the company has worked to optimize the integration between equipment that shares technical specifications and technological platforms.

The goal is to create a unified and robust control ecosystem, which now gains a clear identity: the Nexto System. This initiative aims not only to improve the understanding of Altus solutions but also to facilitate product selection and application by customers, ensuring they have access to a cohesive set of cutting-edge technologies. The Nexto System represents a fundamental step in consolidating Altus's position in the automation market, offering a portfolio even more aligned with industry demands and challenges.

Discover the Nexto System

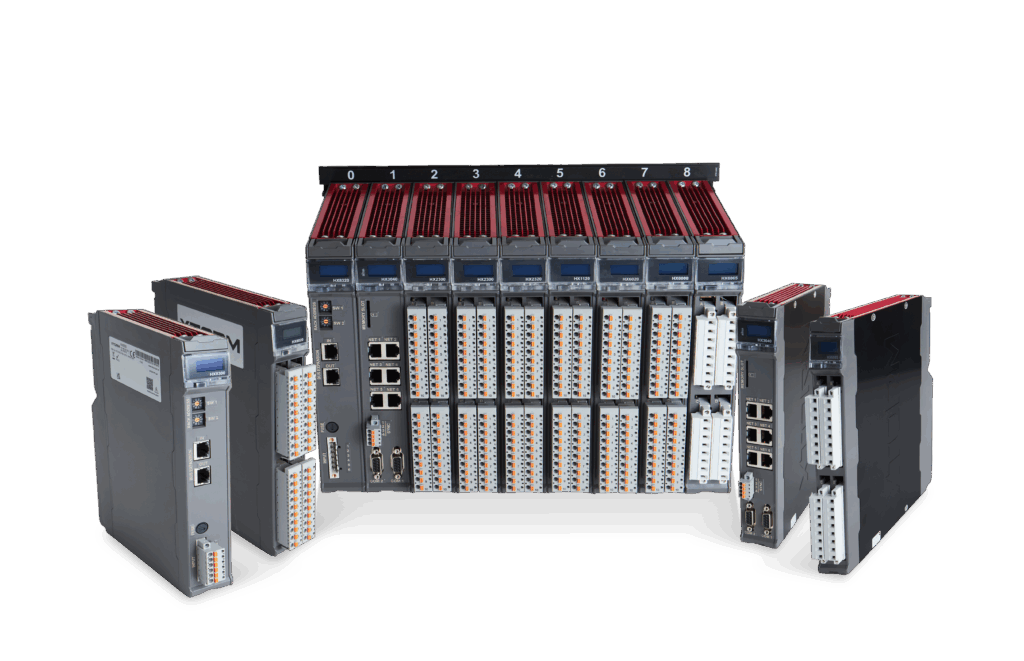

With the launch of the Nexto System, Altus's main equipment families for control and data acquisition are now gathered under a single, comprehensive technological umbrella. This ecosystem integrates products previously known as Nexto, Nexto Xpress, Nexto Jet, Hadron Xtorm, and Nexto Logger, consolidating them into a single platform.

Thus, the Nexto System covers a wide range of automation solutions, such as programmable controllers, remote terminal units, input/output modules, field remotes, dataloggers, among other equipment designed to meet the demands of various industrial segments.

The creation of the Nexto System reinforces Altus's commitment to offering cutting-edge technological solutions that ensure interoperability, efficiency, and flexibility for its customers. All equipment of this new ecosystem use CODESYS technology widely recognized for its reliability and performance in the industrial automation market, and are programmed using our free MasterTool software, which facilitates project development and management.

New naming: more clarity and organization

In addition to the strategic reformulation, the products families included in the Nexto System have received a new naming convention, designed to reflect their specific characteristics and features more clearly and intuitively. This new approach facilitates the identification and selection of equipment, ensuring that our customers can quickly find the most suitable solutions for their needs.

This update in positioning and naming is part of a continuous effort by Altus to simplify access to its solutions, as well as highlight the technological and operational differentials offered by each product line.

NX series: high availability for global automation

The NX series is an innovative product family designed to meet the most demanding industrial automation requirements. With distributed and redundant control capabilities, this series is ideal for managing complex industrial processes, high-performance machines, and smart production line.

This series integrates the programmable controllers and high-performance field equipment from the Nexto series, in addition to the input/output modules from the family previously known as Nexto Jet. This unification reflects technological evolution and Altus's commitment to offering more complete and integrated solutions to the market.

The modern, high-speed NX controllers incorporate cutting-edge technology to ensure operational reliability and broad connectivity, directly contributing to increased business productivity and efficiency.

Key differentiators include:

- - Integrated Distributed Control System (DCS) functions.

- - Equipment with and without hot-swapping support, optimizing maintenance without interruptions.

- - CPU redundancy, ensuring high availability in critical applications.

- - Modular expandability to meet different demands.

- - Scalable architecture based on deterministic Ethernet, ensuring speed and ruggedness in communication.

Thanks to embedded technology, products from the NX series can be applied toat various stages of an application's lifecycle, from initial commissioning to continuous operation.

Click here to learn more about the high-performance products of the NX series

XP series: your gateway to smart automation

The XP series presents the compact controllers previously known as the Nexto Xpress series of IoT-ready PLCs. This equipment was designed to integrate control systems with smart devices, providing efficiency and operational intelligence across a wide range of industrial applications.

XP products stand out for their ability to act as both independent controllers in edge computing solutions and as intelligent gateways, connecting legacy systems to modern digital environments. This flexibility makes the XP series indispensable for companies seeking to increase connectivity and modernize their processes.

Among the most common applications are:

- - Transportation infrastructures.

- - Building automation, promoting energy efficiency, and centralized control.

- - Basic sanitation systems, such as water and sewage.

- - Smart production lines, integrating IoT and automation.

- - OEM machines and motion control in customized industrial processes.

Combining high connectivity, compact design, and advanced IoT features, the XP series PLCs are the ideal choice for projects requiring versatility, reliability, and technological integration.

HX series: ruggedness and versatility for GTD applications

The HX series was developed to meet the challenges of Power Generation, Transmission, and Distribution (GTD) applications. Incorporating the Remote Terminal Units (RTUs) from the consolidated Hadron Xtorm Series, HX products rigorously follow international standards IEC 61850 and IEC 61131-3, ensuring compliance and superior performance.

The main features of this product line include:

- - Power supply redundancy, ensuring continuity in case of failure.

- - CPU redundancy in the same rack, maximizing system availability.

- - Support for essential protocols such as DNP3 and IEC 61850 (MMS and GOOSE).

- - Full compliance with ONS submodule 2.7, aligning with the requirements of the Brazilian electricity sector.

The HX series features a modular architecture, equipped with a powerful 32-bit CPU and a high-speed deterministic Ethernet bus. These features ensure agile and secure communication, even in critical applications. Furthermore, the design was conceived to simplify field operations, such as maintenance, commissioning, and installation, promoting efficiency at all stages of the process.

Click here to explore the advanced solutions of the HX series for power applications

Dynamic data collection and transmission with the NL series

The NL series of dataloggers was designed to meet the needs of monitoring and telemetry in various industrial areas. With cutting-edge technology, these products stand out for high-precision remote data collection and transmission, making them ideal for applications requiring reliable data and continuous operations.

Key application areas include:

- - Power generation, focusing on solar and hydroelectric systems.

- - Hydrological and meteorological stations, monitoring critical environmental parameters.

- - Agribusiness, with solutions for irrigation and soil analysis.

- - Urban, public, and private infrastructures requiring remote sensor control.

NL series’ products offer high performance in projects demanding accuracy in data collection, integrating easily with analysis and control systems. This flexibility makes them essential for applications involving physical quantity monitoring and data-driven decision-making.

Click here to learn more about the NL717

XF series: Advanced connectivity, smart performance

Recently, Altus launched the Nexto XF series, a new generation of Programmable Logic Controllers. This series of modular controllers designed for smart automation functions as a hub of connectivity, performance, and flexibility. Nexto XF CPUs feature a 64-bit dual-core ARM processor (1 GHz), ensuring fast responses and precise control in dynamic and high-speed applications.

With a compact design for DIN rail mounting, these CPUs are ideal for environments with limited space and operate with a 24 Vdc power supply, with low power dissipation. The series also stands out for its high density of embedded I/Os (up to 44 points).

In terms of connectivity, Nexto XF CPUs include 2 Ethernet ports, RS-485, CAN, USB Host, and microSD. They support various protocols such as OPC UA, MQTT, EtherNet/IP, PROFINET, EtherCAT, and MODBUS, being compatible with cloud solutions and IIoT. The series also offers edge computing and virtualization with an embedded Linux platform, enabling the execution of Docker, Python scripts, and CODESYS libraries, optimizing the security and efficiency of local data processing.

Consult our sales team to check product availability.

Access our exclusive page, check out the official video, and fill out the form so you don't miss the next updates on this launch!

Explore the Nexto System solutions

With the Nexto System, Altus is building a future where integration and technological innovation go hand in hand, providing our customers with a unique industrial automation experience. This new approach reflects our commitment to offering solutions that not only meet but exceed the expectations of an ever-evolving market.

Learn about Altus' new product series and discover how they can transform control and data acquisition processes in your industrial plant. The Nexto System was designed to optimize performance, increase ruggedness, and simplify operations,ensuring that your demands for high availability and efficiency are fully met.

Click here to access the system page or fill out the form below to get in touch with one of our specialists to learn more about these product series!