Differentials of a high-speed PLC for machine control

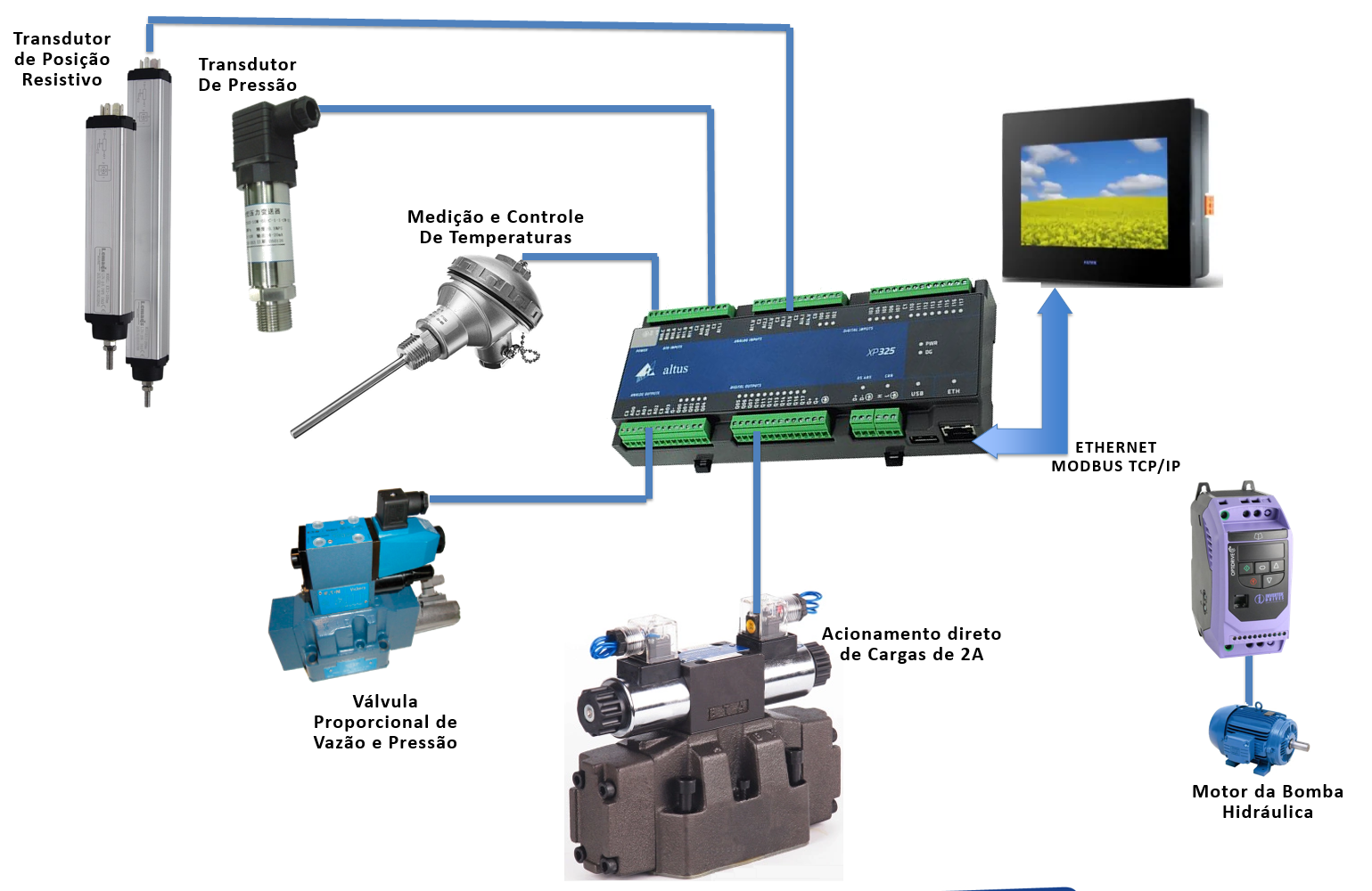

The evolution of the components used on Hydraulic Presses, as well as the better integration of all products, provides a larger increase in the operational efficiency of the control systems. The use of Graphical Interfaces , for example, allows better interaction between the operator and the controlled system. In the case of the hammer control set, we can program the descent speed of the equipment using the position reference as a measurement variable and, through mathematical algorithms, calculate the speed of its displacement, thus having the control variable for a proportional flow valve.

This control was only possible because we currently have PLCs with high capability for arithmetic functions processing. The XP300, part of Nexto Xpress PLC family of compact controllers, is one of Altus` models with the power to execute 1000 floating point instructions in less than 40us .

Speed and power efficiency with Nexto Xpress PLCs

There is no point in having high processing capability if the provided position information, coming from an analog input, do not have a compatible resolution and conversion time. In this regard, the Altus Xpress family once again stands out. The conversion times of the solution`s analog inputs are less than 400us , while the scan time is less than 1ms . In addition, once the mathematical algorithms have been processed, the PLC is able to make the information available on an analog control output with 12-bit resolution and conversion time below 450us.

This is fantastic!

It is also important to highlight power efficiency. In hydraulic systems, when we continuously operate the pump at a nominal speed, we are certainly wasting power, as we do not need the flow and continuous pressure during the entire operating cycle of the machine. Thus, the use of a Frequency Inverter to perform the control, allows the maximization of the application`s performance.

To make the system even more efficient, we can use the CANOpen interface available on all Nexto Xpress PLC models, so we have precise and fast control, preserving digital and analog inputs and outputs to control other machine systems.

It is also important to mention the PLC`s capability to activate Solenoid Valves of up to 40W, which requires 2A of current. This feature, unique in the segment, allows Xpress to obtain transition times for digital outputs from off to on in the order of 20us, and from on to off in less than 500us!

Such capability is fundamental when performance is what we are looking for, as there is no point in having high processing power if peripherals are slow. When we control displacement movements in the order of 1 m/s and we want precision and repeatability, the results obtained with Nexto Xpress PLCs are excellent.

Important tips on engine operation

It is important to observe that the adequacy of the engine speed in relation to the machine demand is an important reason for savings on the operating costs. The operation of the pump in the ideal regime will also allow the increase of the system´s hydraulic components life cycle, as well as the hydraulic fluid reduction of temperature option, the water hammer and, consequently, the oil leaks.

A significant reduction in noise at the work environment can also be noticed, which is extremely healthy.