Road tunnel control system automated with Altus technology

Operating in the industrial automation market for over 40 years, Altus has a wide range of products capable of optimizing processes in the most varied segments. The versatility of the equipment produced and supplied by the company allows them to be used both in machines and industrial plants and in infrastructure and urban mobility projects. Recently, the technology of Altus’ products was applied in the modernization of a road tunnel on the southern Brazil.

The project, developed and implemented by SNEF Brasil, a company that integrates projects and technological solutions, involved the modernization of the automation, communication, control and supervision system of the tunnel, which had an obsolete system, was slow and had several operational problems, such as lack of signaling, false alarms and, in some cases, drive failures. As it is a vital resource for the mobility of the local road network, the system was replaced with the tunnel in operation. This availability demanded that all stages of the project had to occur in a planned and organized manner, avoiding the unavailability of critical systems such as firefighting, cameras and sound system.

High availability solution with Nexto PLC

Having availability as a fundamental factor for the process, the applied architecture was developed using the programmable controllers from Nexto Series as a central piece. With high processing capacity, network redundancy, conformal coating, and hot swapping, Nexto family products were chosen to be the main PLCs of the application, boosting system availability.

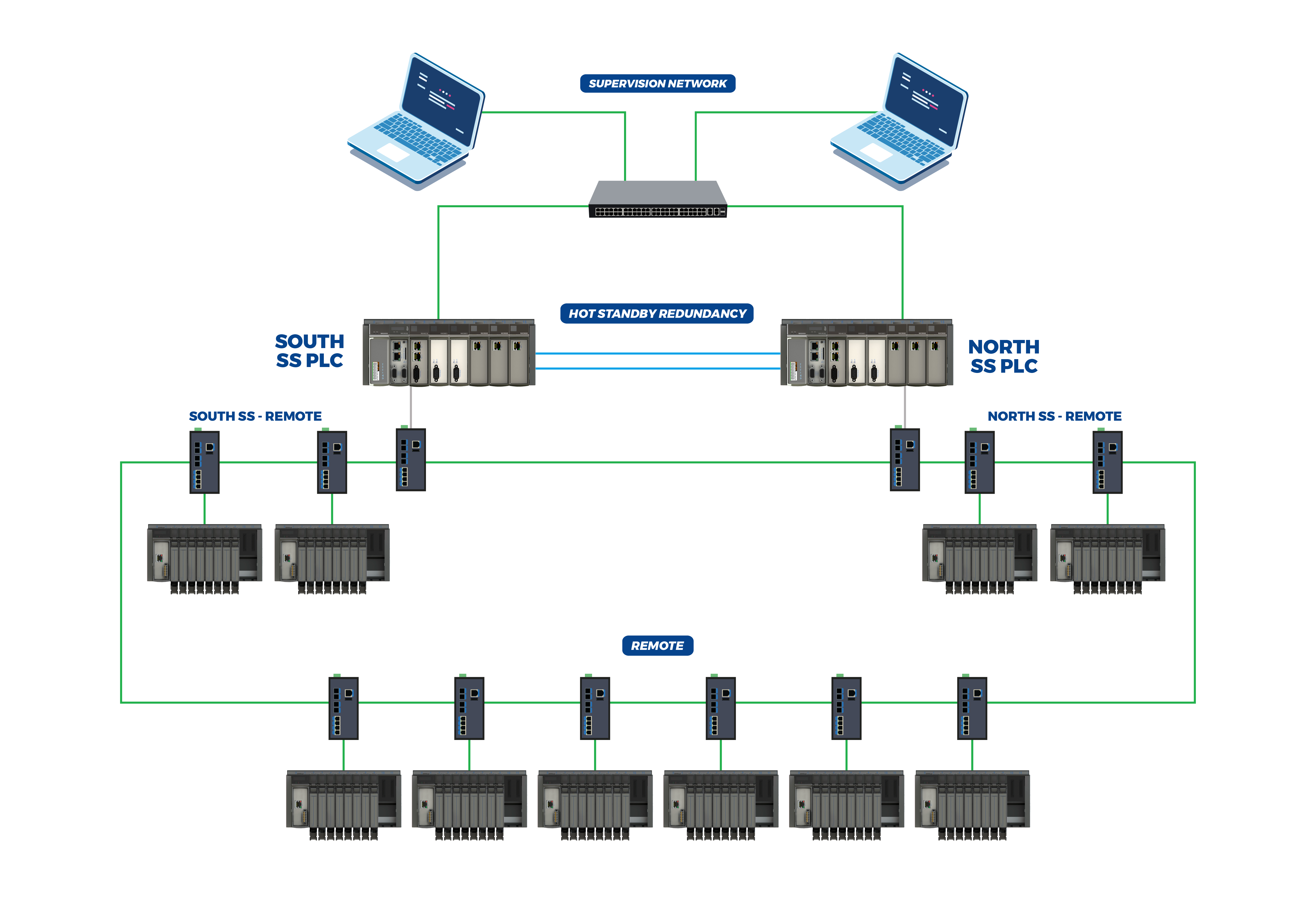

The architecture applied counts on a redundant high availability communication network controlled by two racks with an NX3030 CPU and different communication modules each. The control units operate in hot stand-by mode, redundancy method in which one CPU acts as the primary unit, responsible for controlling the system, while the other remains in reserve state, checking the correct functioning of the primary CPU.

The application counts on 22 racks with remotes and I/O units from Nexto Series, equipment responsible for data collection and activation of the devices that compose the control network. The solution also has industrial switches interconnected in a ring architecture, which guarantees communication between the CPU and the field remotes even if one of the switches stops working.

In this application, Altus equipment is responsible for interacting with generators, nobreaks, visibility sensors, CO2 and Nox levels, soft starters, energy meters and with the power factor controller. The communication with these devices of different technologies is carried out through the MODBUS RTU communication protocols, which uses the Serial standard, and MODBUS TCP/IP, via Ethernet. This equipment is part of the tunnel`s electrical, ventilation and safety systems, critical processes for the operation that cannot be stopped.

Nexto Series PLCs use MasterTool IEC XE programming software. We recently released a new version of the software, with new features and support for more communication protocols.

Click on the banner below and check out the news:

More security and reliability with Altus technology

Felipe Moreira, electrical engineer at SNEF, comments that after the system modernization the concessionaire responsible for managing the project reported a significant increase in the speed of monitoring and commanding the operation. With the implementation of the new solution the system update time, which varied between 20 and 30 seconds in some processes, became instantaneous. Today, the customer can operate the tunnel reliably and safely, with properly trained maintainers to keep system availability.

In addition to the high technology embedded in our PLCs, the technical support of Altus sales and support team was a differential that led to the company being chosen as a supplier for the project. “We considered Altus from the beginning of the process, since it has an extremely qualified technical staff able to help us in any intercurrence”, stated Felipe. Another point highlighted by the customer is the availability of equipment for quick replacements.

“SNEF has been an Altus customer for some years, so we had experience with equipment ranging from the Hadron Xtrom series to Nexto Xpress. Therefore, we were sure of Altus` capacity, both in relation to the representatives who attend us and with the technical support”, commented Felipe. In this project, our Technical Support team also had to be called upon by the customer to assist with an urgent demand: “we had a quick and efficient response. We believe in the ties we have with Altus and we want to continue for many, many infrastructure projects”, he added.