Our Products

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

An exclusive combination of equipment that combines high performance and competitiveness to overcome the challenges of Industry 4.0

At Altus, we have the necessary know-how to provide integrated systems for the most varied demands of the industrial market

Discover our solutions and discover how our expertise can help boost your business performance

See how we have become a reference in the automation market over the course of our more than 40 years

We are 100% available to solve problems, answer questions and help you optimize the performance of your application.

Get to know our units and find out where to find our sales representatives throughout Brazil

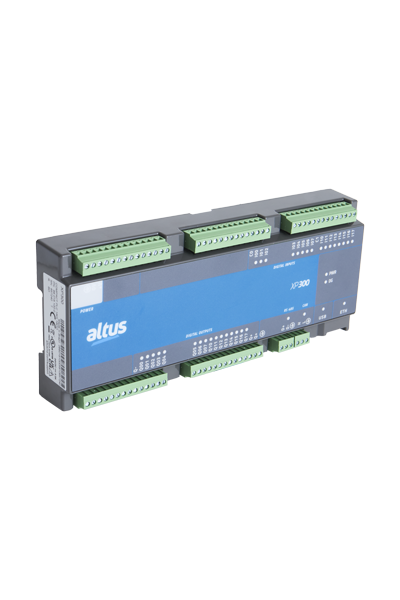

Designed to meet the needs of machines and small-scale processes, the compact XP PLC offers a complete solution for advanced applications, delivering high performance and connectivity with an excellent cost-to-benefit ratio

Varied features for applications in sanitation, building automation, textile, food, transportation, and machinery.

Solid design (212.5 x 90.1 x 32.2 mm) for use in extremely reduced spaces.

Update time less than one millisecond, one of the fastest on the market.

Various options for communication interfaces and support for major Ethernet and Fieldbus protocols.

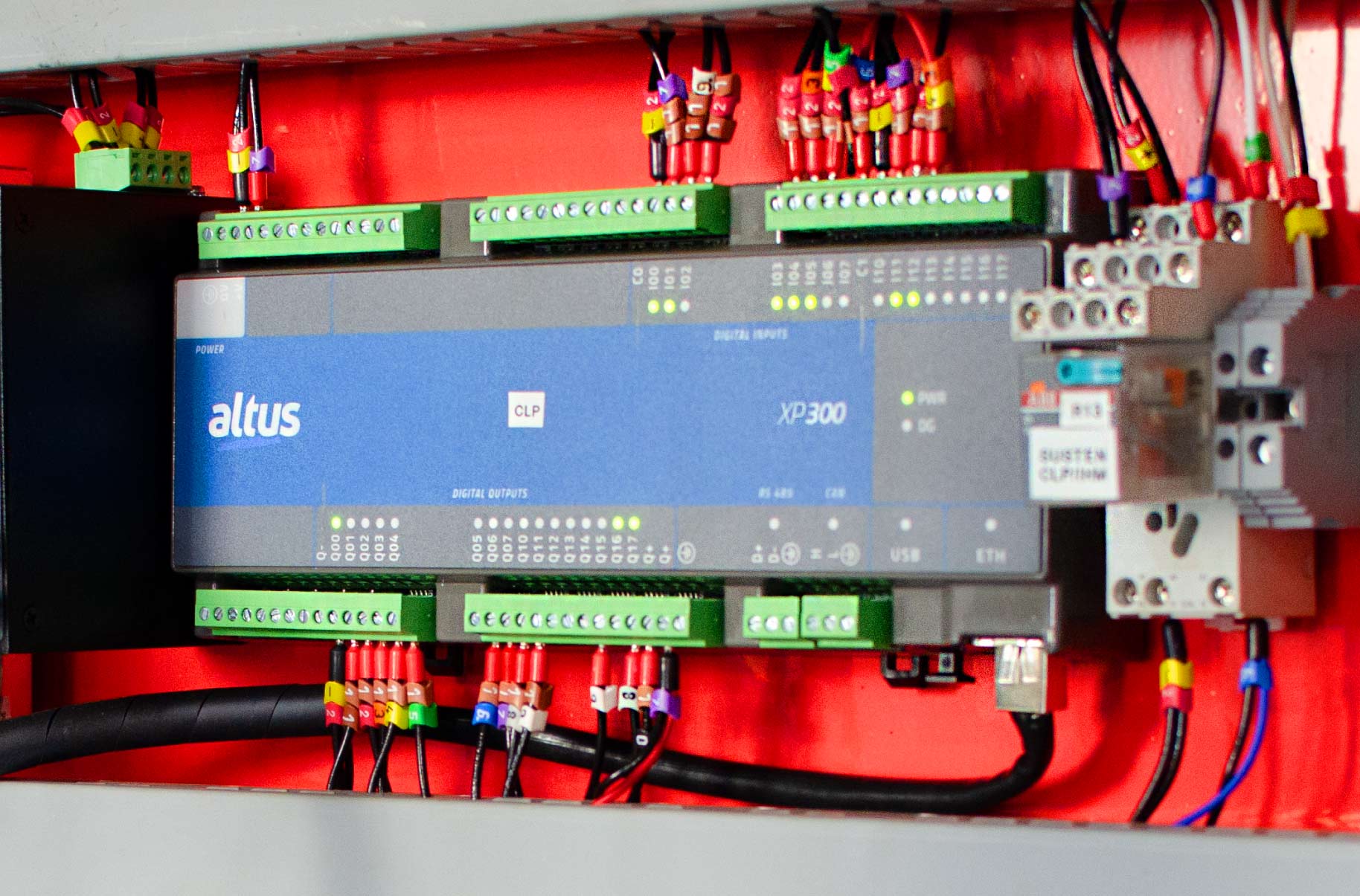

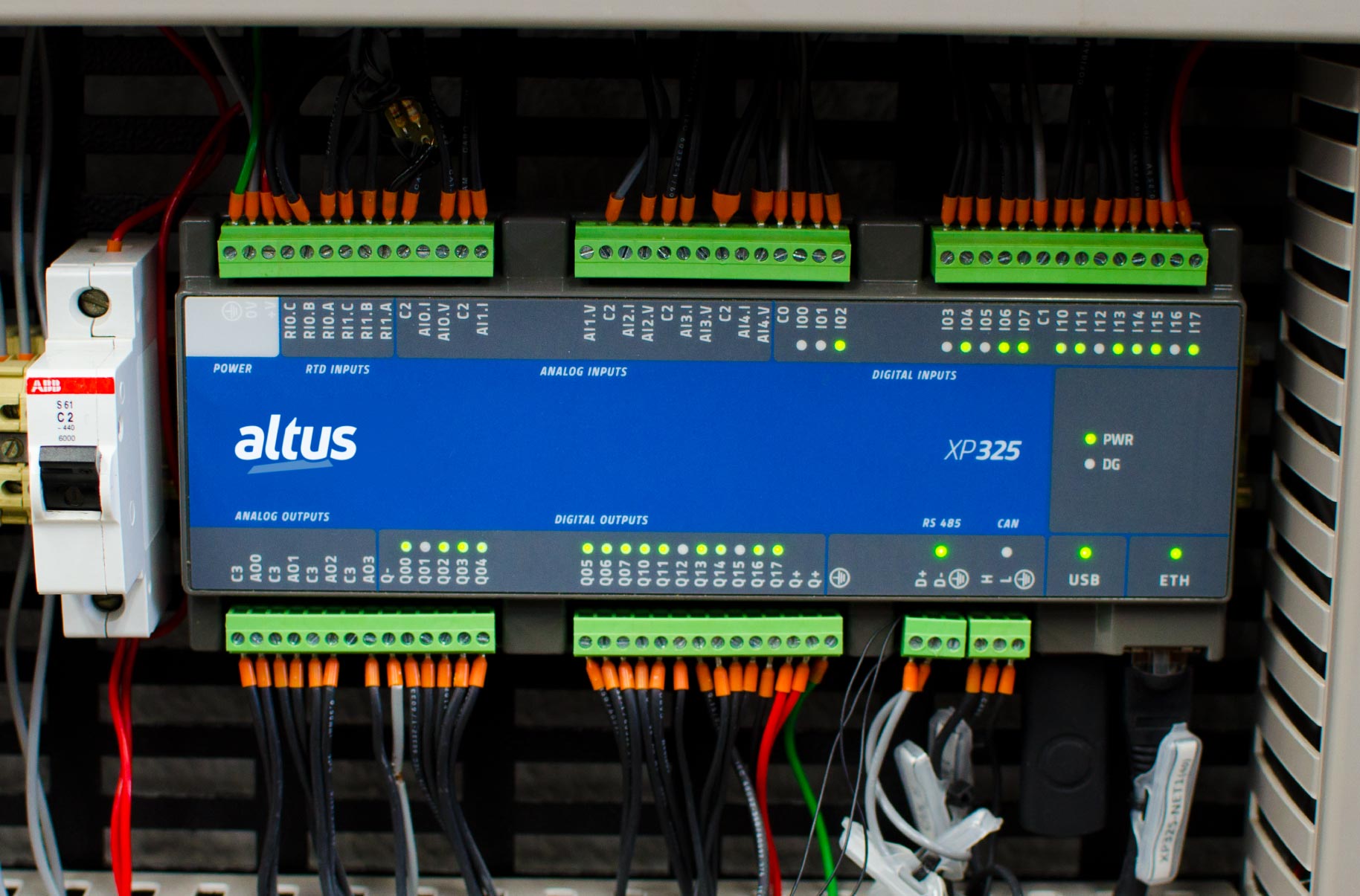

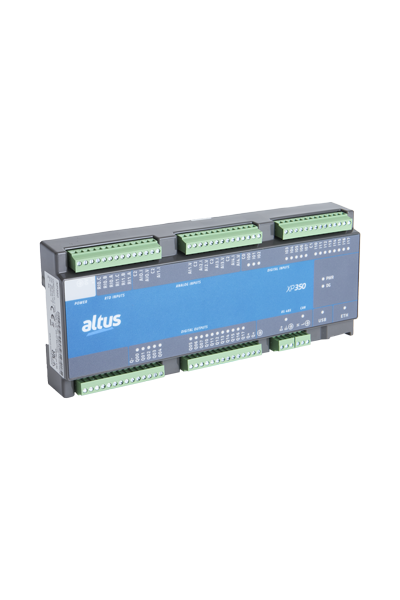

The XP series features five PLC options that differ in the number of points and resources: XP300, XP315, XP325, XP340, and XP350. All feature 16 digital inputs, 16 digital transistor outputs, an Ethernet port, a standard RS-485 Serial channel, a CAN port, and a USB interface. The XP315 and XP350 PLCs also have 2 two- and three-wire RTD analog inputs and 5 analog inputs for voltage and current. The XP325 and XP340 models, on the other hand, have all these features plus 4 analog outputs.

Just like the other members of the Nexto System, the XP series uses the CODESYS technological platform with configuration via MasterTool IEC XE, the series' FREE programming software with scalability for micro to large-scale projects.

Created to meet the demands of highly connected environments, the solution features support for a wide variety of communication protocols, which allows it to interact with the most different types of machines and smart systems. With embedded communication interfaces for Ethernet, Serial RS 485, CAN, and USB, the XP PLCs also feature support for a varied list of communication protocols, such as MODBUS TCP and RTU, PROFINET, CANopen and low level, IEC 60870-5-104, EtherNet/IP, OPC DA, OPC UA, and MQTT.

The controllers can communicate directly with the most relevant cloud hosting services on the market, such as Microsoft Azure, IBM Cloud, Google One, and Amazon AWS. Through the MQTT protocol, the products can interact with different brokers in order to communicate with web service platforms, such as Node-Red, and deliver information directly to tablets, smartphones, and other mobile devices.

With a compact design (212.5 x 90.1 x 32.2 mm) and 24 Vdc power supply, the XP series is ideal for the embedded control of machines and small-scale applications. Its 32-bit ARM processor, combined with the real-time clock (RTC) and the high density of multi-purpose digital and analog I/O points (voltage, current, and temperature), give the solution a high processing capability, precision, and agility in data acquisition.

These features make the XP series the ideal solution to enhance both speed and cost-efficiency in controlling a variety of machines, such as labeling machines, blow molders, washers, injection molding machines, baggers, grinders, presses, and more.

The PLCs also come equipped with LED indicators for status and diagnostics, DIN rail mounting, and removable connectors.

The USB port integrated into XP PLCs allows communication with a wide range of smart devices, such as media converters, barcode readers, wireless communication modems, and data storage devices. This feature also supports 3G/4G modems and Wi-Fi adapters, enabling the products to connect to wireless networks, whether corporate or cellular, anywhere they are deployed.

This capability allows the controller to utilize available 3G/4G networks to transmit data from remote process units back to command centers without the need for dedicated infrastructure. Another use case includes connecting with IoT devices and machines on the same Wi-Fi network, a common feature in smart production lines.

XP programmable controllers features digital outputs supporting up to 1.5 A per channel (12 A max) and analog inputs with 12-bit resolution, updating all channels in less than a millisecond—one of the fastest systems available. This array of features allows the platform to handle larger systems, such as those found in building automation and sanitation projects.

With precise variable control, the XP PLC can manage tasks like pumping stations and reservoir level control, as well as the processes tied to Building Management Systems (BMS), including lighting, climate control, process supervision, transport systems, and access control.

With a compact design, DIN rail mounting, and low energy consumption, the XP input and output expansion modules make it possible to increase the number of sensors and actuators used in the most varied applications. The series' equipment is suitable for building automation solutions, water and sewage, food and textile industries, machinery, and various OEM solutions.

Furthermore, the products can be applied in conjunction with all CPUs from the Nexto portfolio, acting as a complement for architectures from small to large applications, an important characteristic for system integrators with projects of different scales.

Available modules:

XP101 – 16 digital inputs

XP106 – 8 digital inputs and 6 relay digital outputs

XP201 – 16 digital transistor outputs

XP600 – 4 analog inputs for voltage/current

XP610 – 4 analog outputs for voltage/current.

To provide users with greater flexibility and speed in developing small- and medium-sized applications, the XP340 PLC includes a built-in WebServer, allowing you to create monitoring and supervision screens without the need for SCADA software. This feature is embedded in the programmable controller’s memory and can be accessed through any web browser on devices (computers, tablets, or smartphones) connected to the network. This remote-control functionality not only offers convenience but also delivers significant project cost savings by eliminating the need for dedicated supervision equipment and software.

All controllers in the XP series feature an embedded VPN, a feature that allows for the creation of a private connection tunnel directly between the PLC and the installed application in the field. The functionality allows you to access your business's control network remotely and completely securely. To further increase the product's security, the PLCs also feature an integrated firewall.

Designed for applications requiring high precision, such as packaging machines and assembly lines, the XP350 is the first PLC in the Nexto System to support Motion Control. The product can operate in loops with up to 4 motion control axes (X, Y, Z, and A), supporting PLCopen Motion Control Part 1 function blocks for single-axis control, multi-axis synchronization, electronic camming (CAME), and a dedicated editor for movement planning (CAM).

Get to know the XP350 PLC

The XP PLC also supports FTP connections, enabling it to exchange data with servers using this technology. This functionality allows data packages generated by the controller, such as logs recorded via a datalogger function, to be accessed remotely.

Another great functionality available on XP products is the ability to write directly to Microsoft databases using the SQL language.

Speed and cost-efficiency for controlling labelers, blow molders, washers, injection molding machines, baggers, grinders, presses, and more.

Ideal for building automation, including lighting and climate control, process supervision, transport systems, and access control.

Precise variable control for sanitation industry applications, such as remote-control stations, pumping stations, and reservoir level management.

Nexto XP Expansion, 16 DI 24 Vdc

Nexto XP Expansion, 8 DI 24 Vdc and 6 DO Relay

Nexto XP Expansion, 16 DO Transistor

Compact PLC with high-speed CPU, 1 Ethernet port, 1 serial channel, 24 Vdc 16 DI and 16 DO transistor

Compact PLC with high-speed CPU, 1 Ethernet port, 1 serial channel, 24 Vdc 16 DI, 16 DO transistor, 5 AI voltage/current and 2 AI RTD

Compact PLC with high-speed CPU, 1 Ethernet port, 2 serial channels, 24 Vdc 16 DI, 16 DO transistor, 5 AI voltage/current, 2 AI RTD and 4 AO voltage/current

Compact PLC with high-speed CPU, 1 Ethernet port, 2 serial channels, 24 Vdc 16 DI, 16 DO transistor, 5 AI voltage/current, 2 AI RTD, 4 AO voltage/current and Web Server support.

Compact PLC with high-speed CPU and Standard Softmotion, 1 Ethernet port, 1 serial channel RS-485, 1 CAN interface, 1 USB, 24 Vdc 16 DI, 16 DO transistor, 5 AI voltage/current and 2 AI RTD

Nexto XP Expansion, 4 AI voltage/current

Nexto XP Expansion, 4 AO voltage/current

Nenhum produto encontrado.

Av. Theodomiro Porto da Fonseca, 3101, lote 01 – São Leopoldo/RS – Brasil

CEP 93022-715

© 2025 Altus

Criação de sites pela Agência de Marketing Digital Orgânica Digital.