Digital Transformation of YPF Brasil uses Altus PLC technology

In an increasingly fast and dynamic market, it is essential that companies of all sizes promote digital transformation and adaptation actions in order to maintain their competitiveness and high productivity. As a reference in the development and production of equipment for industrial automation in Latin-America, Altus is able to provide technology to promote the digitization of processes for companies in the most different segments. In order to start a transformation in its production unit in Brazil, one of the biggest companies in exploration and production of hydrocarbons in South-America sought in Nexto Series programmable controllers the technology necessary to adapt its processes to the demands of connectivity, security and high productivity of Industry 4.0.

Altus products were used in the modernization of its Brazilian branch, the company has been present in the Brazilian market for 25 years and has a production capacity of up to 47 thousand tons per year. By promoting a digital transformation using the technology of Altus products, the company gained more performance and production capacity, also adding an extra layer of operational and environmental safety to its processes.

Control and supervision solution with Altus products

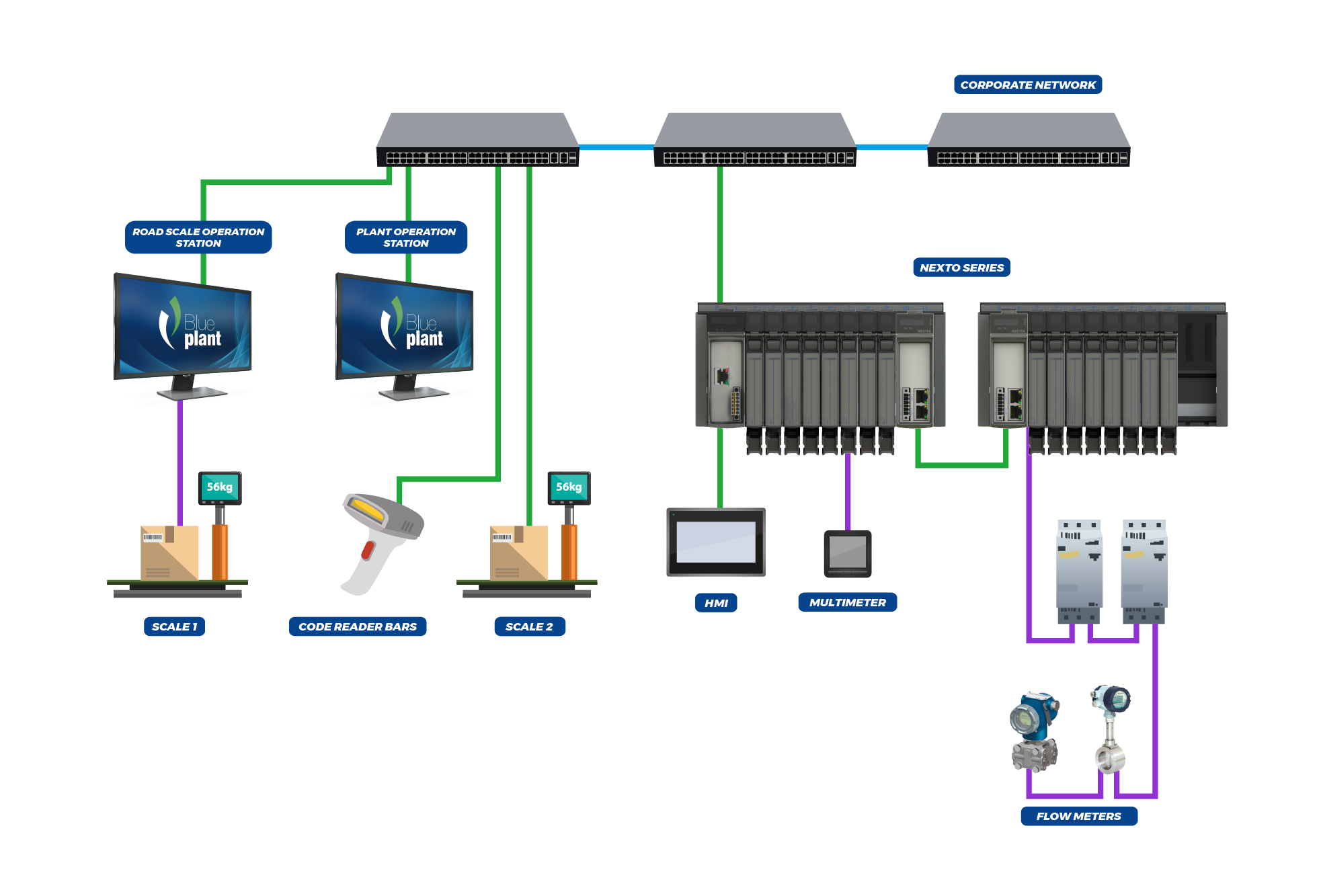

Our products are present in practically the entire production line of the company, being responsible for the control of different systems like the ante-transshipment systems, pressure control for blocking pumps and operational blocks, product recipes preparation, production line and filling safety, as well as the line cleaning system (PIG). The implemented architecture is based on an NX3005 control unit, Nexto line CPU with high processing speed and large data storage capacity, integrated power supply and embedded WebServer. The PLC acts as the center of the control and supervision solution, processing the data collected by the field instruments and interacting with local and remote supervision resources.

The solution has two control networks: one operating in MODBUS RTU and the other in MODBUS TCP, both controlled by a bus with the NX3005 CPU and I/O modules of different models, in addition to an expanded bus with more input and output cards. This composition is responsible for collecting data, activating and adjusting field instruments such as analog and digital sensors, floats, pneumatic valves, relays, inverters and soft-starters, pressure transmitters and flow meters.

The NX3005 PLC from the Nexto Series of programmable controllers has several advanced features, high performance, and flexible architecture, which allows its use in small to large automation systems. Its compact and robust structure, combined with high processing speed, which exceeds 1,000 Boolean instructions every 6 microseconds, and huge data storage capacity, makes the CPU a great choice for the most demanding control and automation applications. The unit also has a bult-in WebServer, which allows the creation of application supervision and monitoring screens without the need to use a SCADA system.

In addition to the Nexto buses, the architecture also relies on an energy multimeter, responsible for monitoring consumption and the quality of electrical energy in the operation. For local supervision and recipe entry, the solution has a 10” ethernet capable HMI. Remote supervision is provided by the BluePlant SCADA/HMI software, Altus` solution for supervision, control and data acquisition.

Are you interested in knowing more details about any of these products? Fill out the form at the end of this article to request contact from our Commercial team. One of our specialists will contact you to talk about our solutions and demonstrate how Altus technology can contribute to the performance and safety of your operation.

The benefits of using Altus technology

An Automation Technician who participates in the digital transformation process at the company points out that the main benefits that the company realized after implementing the solution were an important increase in the quality of the manufactured product and greater control in terms of safety environmental. “We chose to use Altus products in this project because it is a consolidated company, with 40 years in the market, and also due to our policy of prioritizing the national industry”. The applied control and supervision solution allowed the optimization of the plant`s production processes and added greater safety to the unit in general.

In addition to providing the technology for the digital transformation of the industry, Altus also provided engineering intelligence through the expertise of its specialists, who worked on the automation of the plant`s production machines.

Discover the Nexto family of modular PLCs

Nexto PLC is an advanced automation system capable of controlling complex industrial processes, machines and high-performance production lines in a distributed and redundant manner. Modern and high-speed, the Nexto Series uses state-of-the-art technology to provide reliability and connectivity, contributing to increase your business productivity.

Preemptive and multitasking, the operating system of Nexto CPUs allows for sophisticated applications. With powerful 32-bit and 64-bit RISC PowerPC and ARM processors, the family`s PLCs are able to perform complex arithmetic calculations and advanced control functions, more than 145,000 Boolean instructions or more than 500 PID loops per millisecond. The series uses the MasterTool IEC XE programming software, a system based on the CODESYS platform and free of charge for applications with up to 320 I/O points.

We recently released a new version of the software, with new features and support for more communication protocols. Click on the banner below and check out the news:

The most recent model of the family is the NX3008, the new Nexto Series CPU, a global product with advanced software and cybersecurity functionalities capable of dynamically integrating the IT and TA areas of an industry. Created to meet the demands of an increasingly connected industry, the NX3008 CPU has a wide variety of communication interfaces capable of connecting the equipment to the most different systems and machines on the market. The new Nexto Series control device has 03 Gigabit Ethernet ports, 02 of which support the PROFINET Controller communication protocol, which allows the controller to be used in a network with MRP ring architecture. For applications that cannot stop, the Nexto family has redundant CPUs and hot-swappable modules, resources that practically eliminate the need to stop the system for maintenance. The series also has I/O module expandability without system downtime and automatic module addressing in the rack.

Through ports integrated into the CPUs and communication interfaces, the Series offers hardware and software support for the following fieldbus protocols: