First American hydrogen powered catamaran uses Xpress technology

Responsible for 15% of all cargo transported in the United States in 2021, the waterway modal is an important logistics resource in the country and has constantly invested in technological modernization. Recently, an important North American marine shipyard responsible for the construction of advanced vessels saw in Altus the necessary technology to modernize the automation system of its fleet and develop America`s first hydrogen powered catamaran. The scope of the project foreseen the update of multiple processes in different parts of the ships.

Developed by Bluefin Marine, a systems integrator in North America linked to our partners at Beijer Electronics, the main purpose of the modernized system is to automate the start and stop procedures of onboard pumps and fans. However, the application is also responsible for monitoring different operating variables through digital and analog points installed along the boat, collecting data relating the state of the vehicle.

More details after de video!

Rugged and high performance with Nexto Xpress PLCs

To ensure that these activities are carried out as expected, it is essential to observe some indicators, including interior temperature, bilge and tank levels, hydrogen fuel cell cooling, backup, shutdown, status and monitoring. With high speed and high reliability, as well as the conformal coating process that each printed circuit board goes through before the assembling of the product, Nexto Xpress programmable controllers were the solution chosen to compose the control system and ensure the operability of these processes.

To ensure that these activities are carried out as expected, it is essential to observe some indicators, including interior temperature, bilge and tank levels, hydrogen fuel cell cooling, backup, shutdown, status and monitoring. With high speed and high reliability, as well as the conformal coating process that each printed circuit board goes through before the assembling of the product, Nexto Xpress programmable controllers were the solution chosen to compose the control system and ensure the operability of these processes.

To increase its robustness, Nexto Xpress products also undergo a conformal coating. In the process, a thin layer of non-conductive material is applied to the product plate to protect against corrosion, extreme temperatures, salty air, humidity, among other factors.

Also, the PLCs from the Xpress family are in compliance with the DNV global standard. The series equipment are certified on Type Approval category, what makes them completely ready to be used in maritime applications, such as control systems in yachts, cruising ships, cargo vessels and Oil & Gas platforms.

Click here and check the Altus registration on the DNV website.

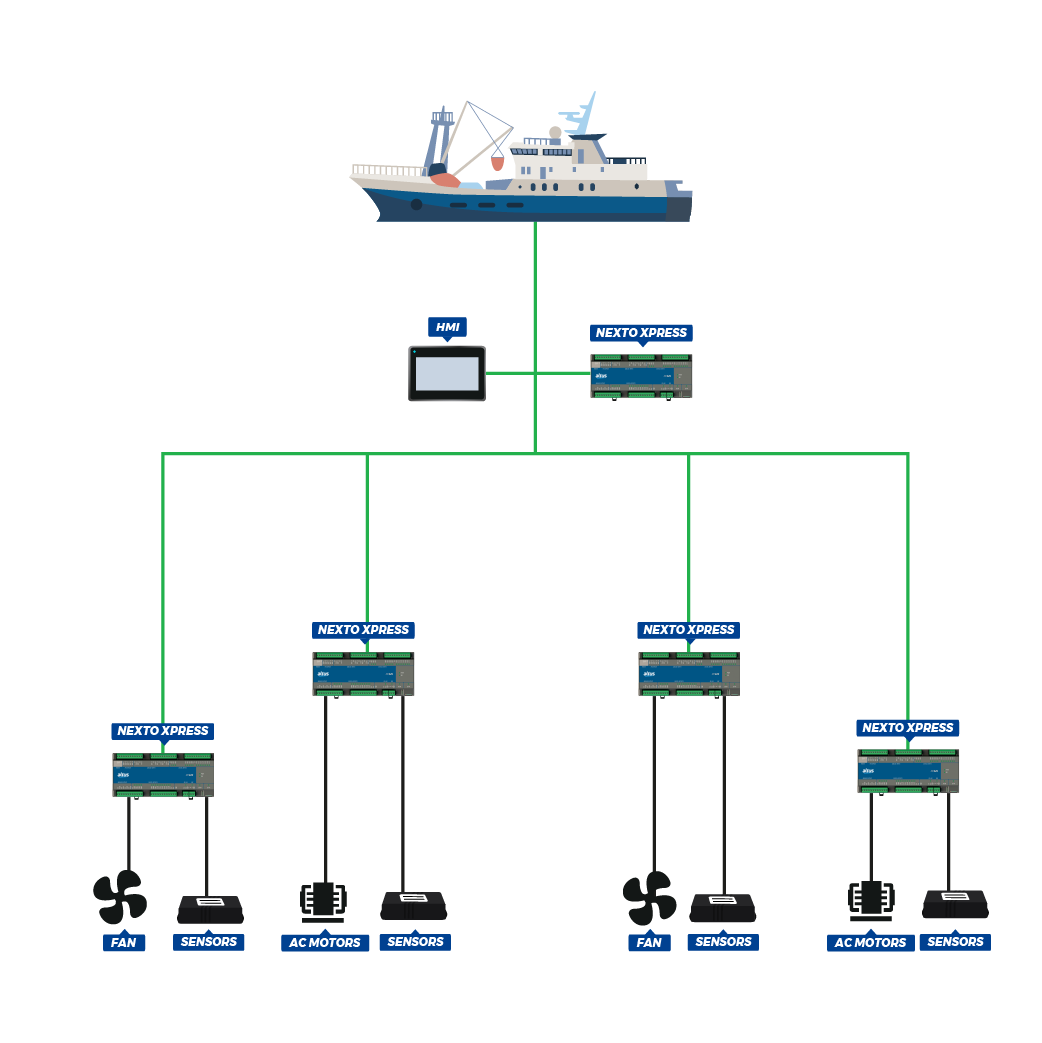

High connectivity architecture

The applied architecture counts on five XP315, one of Altus` IoT ready PLC models, and one 15” HMI. Four of the controllers are on separate Motor Control Center cabinets in places adjacent to the fuel cell room and in each hull. They control the drives responsible to start and stop the onboard pumps and fans through a CANopen network. The controllers also collect data from the sensors and devices monitoring the variables of the system. The fifth PLC, as well as the HMI, is located in the bridge control.

The controllers in the MCC cabinets and the XP325 in the bridge control are connected to the HMI through an Ethernet network and communicate with it using the OPC UA protocol.

Versatility and high communication capacity with Nexto Xpress

Its unique concept of compact design with high density of I/Os enabled the customer to include a PLC in each MCC cabinet to control the auxiliary loads, eliminating a large number of conductors from the engine room up to the bridge control, resulting in a significant cost reduction to the automation budget.

Dave Bechtel, owner of Bluefin Marine, comments that the large variety of communication resources embedded on Nexto Xpress products was one of the differentials that led the PLC to be chosen as a control solution for the application. “The diversity of communication interfaces and protocols available in the product is fascinating, it makes it easy to communicate with different smart devices”, says Dave.

Another benefit from the usage of Altus IoT ready PLCs are the savings related to development costs. As it features embedded analog interfaces, the solution requires low engineering investment for configuration, resulting in a high-performance application with enhanced savings.