Os investimentos contínuos da Altus em pesquisa e desenvolvimento proporcionam a concepção de equipamentos de alta tecnologia, soluções aderentes à realidade da indústria internacional e capazes de suprir as mais variadas demandas de diferentes segmentos. Essa veia inovativa faz parte do DNA da empresa, característica intrínseca em cada uma das linhas de produtos lançadas ao longo de seus quase 40 anos de história.

Os investimentos contínuos da Altus em pesquisa e desenvolvimento proporcionam a concepção de equipamentos de alta tecnologia, soluções aderentes à realidade da indústria internacional e capazes de suprir as mais variadas demandas de diferentes segmentos. Essa veia inovativa faz parte do DNA da empresa, característica intrínseca em cada uma das linhas de produtos lançadas ao longo de seus quase 40 anos de história.

Você pôde ver parte dessa história na publicação sobre as séries AL, Destro, Piccolo e Quark, nossas primeiras famílias de produtos, lançadas entre as décadas de 1980 e 1990, e no conteúdo que trouxemos sobre as séries Ponto, Duo e Nexto, dispositivos das nossas terceira e quarta gerações de CLPs. Agora, dando sequência a essa série sobre a história dos controladores programáveis Altus, vamos falar sobre o produto que abriu as portas de muitas empresas para o universo da Indústria 4.0: os CLPs IoT ready da família Nexto Xpress.

Um CLP feito para o mercado

Os primeiros rascunhos do que viria a se tornar a família Nexto Xpress foram traçados em dezembro de 2017, através de uma análise do cenário mundial da automação na época. Porém, a história do CLP começou muito antes dessa data. A gênese do equipamento se confunde com o próprio surgimento da empresa, uma vez que o conceito que norteou toda a trajetória de desenvolvimento do produto é um dos principais valores da Altus: Foco no Cliente! Criado para atender às demandas do mercado de máquinas e pequenos processos, o controlador foi projetado com base nas urgências da indústria, um produto 100% customer-driven.

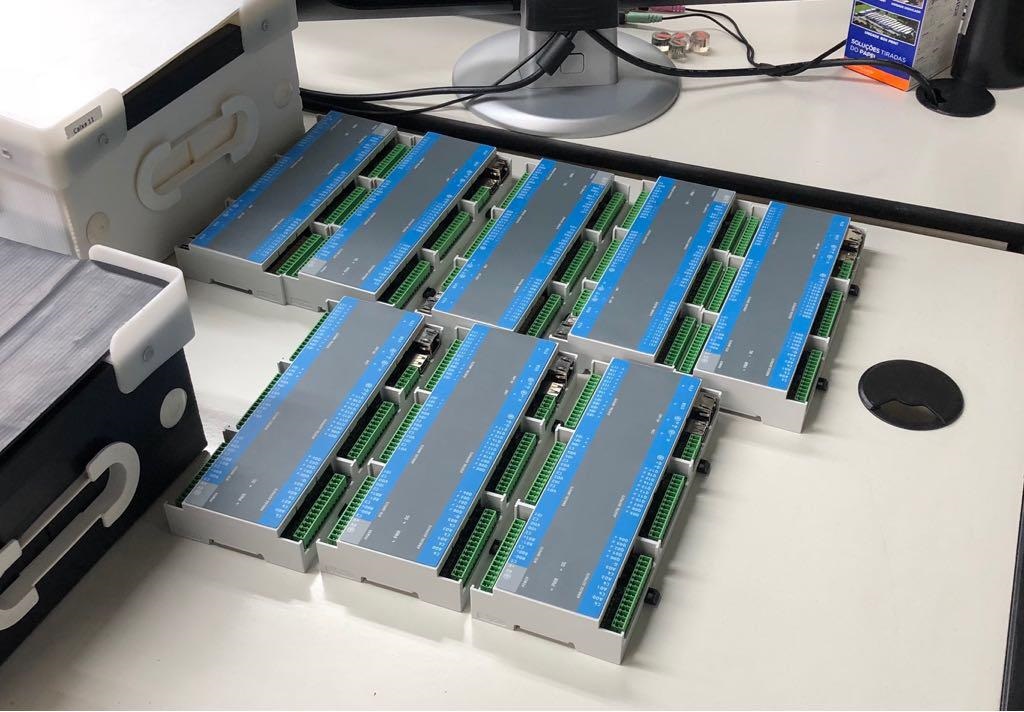

Primeiros modelos para teste do CLP Nexto Xpress

Além de ter alta aderência às necessidades do mercado, os produtos da família Xpress também foram projetados para atender às demandas de outra importante vertente que ganhava força e destaque na época: as tecnologias da Quarta Revolução Industrial. Com processamento avançado e múltiplos recursos de conectividade, os CLPs da família podem ser utilizados em sistemas ligados a praticamente todos os pilares da Indústria 4.0. Os recursos embarcados nos controladores Nexto Xpress habilitam os produtos a serem utilizados tanto em aplicações de Integração de Sistemas e Internet das Coisas, áreas onde CLPs já são tradicionalmente utilizados, quanto em sistemas de Edge Computing, Cloud Computing, Big Data e Data Analysis, segmentos de TI cada vez mais explorados em sistemas de automação.

Processo de testes do CLP Nexto Xpress

Processos de gravação das placas e de injeção da mecânica

Nexto Xpress, o all-in-one PLC da Altus

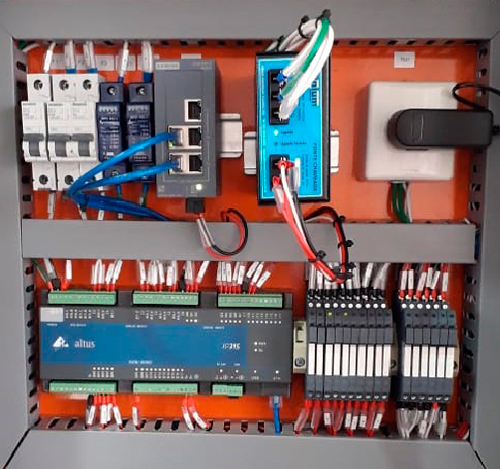

Compacto e multiprotocolo, o controlador Xpress foi desenvolvido para ser um verdadeiro all-in-one PLC. Fabricado com apenas uma placa de circuito e um processador multi-task com diversos recursos embarcados, o produto facilita o processo de industrialização e pode ser utilizado em aplicações de diferentes propósitos, desde máquinas de self service e pequenas automações prediais até em sistemas distribuídos em grandes indústrias. O fato de a família contar com conformal coating também é diferencial para um controlador pequeno como o Xpress. No processo, uma fina camada de material não condutor é aplicada na placa do produto para proteção contra corrosão, temperaturas extremas, maresia, umidade, entre outros fatores.

Com interfaces de comunicação Ethernet, Serial RS 485, CAN e USB embarcadas, os produtos Xpress são capazes de suportar uma ampla variedade de protocolos de comunicação. Hoje, todos os modelos da linha contam com suporte aos padrões MODBUS TCP e RTU, CANopen e low level, IEC 60870-5-104, EtherNet/IP Scanner, OPC DA, OPC UA e MQTT. Essa variedade de possibilidades de comunicação permite que os CLPs compactos da Altus interajam com os mais variados dispositivos e recursos inteligentes encontrados na indústria, desde máquinas e CLPs de diferentes fornecedores até dongles WiFi, storages e sistemas de ERP externos.

Essas características fazem com que o CLP possa ser utilizado nos mais variados ambientes da indústria, como em aplicações do mercado de Saneamento e de Energia. Ao longo dos últimos anos, os controladores Xpress têm sido aplicados nas mais diferentes aplicações, como nos sistemas de tratamento de água e esgoto da CAGEPA e SABESP, quanto no sistema de eficiência energética desenvolvido pela SEER. Em ambos os casos, a alta taxa de conectividade dos produtos Altus foram o fator determinante para o sucesso do projeto.

Essas características fazem com que o CLP possa ser utilizado nos mais variados ambientes da indústria, como em aplicações do mercado de Saneamento e de Energia. Ao longo dos últimos anos, os controladores Xpress têm sido aplicados nas mais diferentes aplicações, como nos sistemas de tratamento de água e esgoto da CAGEPA e SABESP, quanto no sistema de eficiência energética desenvolvido pela SEER. Em ambos os casos, a alta taxa de conectividade dos produtos Altus foram o fator determinante para o sucesso do projeto.

Para agregar ainda mais versatilidade aos sistemas em que são utilizados, os produtos da família também possuem características que os possibilitam a atuar tanto em aplicações de Cloud Computing quanto de Edge Computing. Os CLPs Nexto Xpress possuem uma capacidade nativa de comunicar diretamente com os serviços de hospedagem na nuvem mais relevantes do mercado, como Microsoft Azure, IBM Cloud, Google One e Amazon AWS.

Um exemplo de onde esses recursos são amplamente utilizados são as soluções didáticas desenvolvidas para utilização em laboratórios técnicos de variadas instituições de ensino. Recentemente, a tecnologia dos CLPs foi utilizada na montagem do Centro de Treinamento e Desenvolvimento da Indústria 4.0 do SENAI Minas Gerais, um empreendimento para fomentar a jornada 4.0 na indústria nacional. Os equipamentos também são utilizados para capacitação técnica de alunos e jovens profissionais em outras unidades do SENAI e em diferentes universidades e escolas técnicas de todo o Brasil.

Para completar, o modelo XP340 ainda conta com suporte a WebServer, ferramenta que permite a criação de telas de supervisão e monitoramento de aplicação sem a necessidade de usar um sistema SCADA.

Alta velocidade para máquinas de múltiplos propósitos

Com design compacto (212,5 x 90,1 x 32,2 mm) e alimentação 24 Vdc, a solução Xpress é ideal para o controle embarcado de máquinas e aplicações de pequeno porte. Seu processador ARM 32 bits, aliado ao relógio de tempo real (RTC) e a alta densidade de pontos de E/S digitais e analógicos de múltiplo propósito (tensão, corrente e temperatura) dão à solução uma elevada capacidade de processamento, precisão e agilidade na aquisição de dados. Estas características colocam os equipamentos como a solução perfeita para dar mais velocidade e economia no controle das mais variadas máquinas do mercado, como rotuladoras, sopradoras, lavadoras, injetoras, ensacadoras, moedores, prensas, entre outras.

Com design compacto (212,5 x 90,1 x 32,2 mm) e alimentação 24 Vdc, a solução Xpress é ideal para o controle embarcado de máquinas e aplicações de pequeno porte. Seu processador ARM 32 bits, aliado ao relógio de tempo real (RTC) e a alta densidade de pontos de E/S digitais e analógicos de múltiplo propósito (tensão, corrente e temperatura) dão à solução uma elevada capacidade de processamento, precisão e agilidade na aquisição de dados. Estas características colocam os equipamentos como a solução perfeita para dar mais velocidade e economia no controle das mais variadas máquinas do mercado, como rotuladoras, sopradoras, lavadoras, injetoras, ensacadoras, moedores, prensas, entre outras.

Recentemente, os produtos Xpress foram utilizados na modernização das máquinas para envase de iogurtes e bebidas lácteas da Josmaq, onde a arquitetura aplicada na máquina tem como peça central do sistema de controle o XP300. Os equipamentos da família também aparecem como peça central do sistema de controle da máquina de termociclagem da Odeme Dental Research. Desenvolvido para a realização de pesquisas científicas na área da odontologia, o equipamento atua no processo de envelhecimento acelerado de resinas compostas e outros materiais dentários através de choques térmicos, utilizando um CLP XP315.

Outro ponto de destaque para este mercado é o custo de implementação dos produtos Xpress. Todos os modelos da família requerem baixo HH de engenharia para configuração e entregam elevado desempenho para leitura de sinais, resultando em aplicações de alta performance e baixo custo, cenário ideal para fabricantes de máquinas.

Um produto feito para o mercado internacional

Além de possuir todas as qualificações para ser aplicado nas mais variadas demandas da indústria brasileira, o CLP Nexto Xpress é completamente aderente às exigências e padronizações do mercado internacional. Os produtos da linha foram projetados para seguir os requisitos de Ecodesign da diretiva RoHS, que proíbe a utilização de determinadas substâncias perigosas no processo de fabricação dos equipamentos, desde seus insumos mais simples até a embalagem de transporte. Essas características, aliadas a outros preceitos, também colocam a família Xpress em conformidade com a marcação CE, que permite a sua comercialização no bloco europeu.

Além dessas duas marcas, garantias de confiabilidade no mercado global de eletrônicos, os controladores Xpress também contam com as certificações UL e CUL. Emitidas pelo laboratório Underwriters Laboratories, as certificações são requisito obrigatório para exportação de produtos para os Estados Unidos e o Canadá, o que permite à Altus explorar ambos territórios no hemisfério norte e reforça o conceito da Série Nexto como um produto de classe mundial. Ainda, para dar mais abrangências à linha, os CLPs Xpress também contarão com o selo DNV-GL, requisito em alguns países para utilização dos controladores em aplicações marítimas, como sistemas de controle em iates, cruzeiros, navios cargueiros e plataforma de produção de óleo e gás. O processo de certificação já foi iniciado com o laboratório Det Norske Veritas e deverá ser concluído até final de 2021.

Por ser um produto de altíssima tecnologia embarcada e aderente a todas essas importantes certificações, podemos afirmar que o Nexto Xpress é um CLP com vocação para ser uma estrela internacional. Essa aptidão para os projetos mais versáveis já chamou a atenção do mercado global, que tem demandado cada vez mais do produto, aumentando a abrangência dos equipamentos da Altus.

Hoje, os produtos da família Xpress estão presentes em cada um dos cinco continentes habitados do planeta através das mais diferentes aplicações. Entre os principais países onde a tecnologia Altus se faz presente estão Alemanha, Índia, Turquia, Itália, Suécia, Emirados Árabes, África do Sul, Marrocos, Canada, Holanda, Taiwan, Austrália, Noruega, China, Reino Unido, Estados Unidos, entre outros.

São muito os territórios conquistados pelos controladores programáveis Nexto Xpress nesses primeiros três anos de existências da solução. Assim como seus predecessores, nossos CLPs compactos também recebem upgrades pontuais para agregar novos recursos e seguir atendendo às demandas da indústria internacional. Esse processo de melhoria constante faz parte do DNA da Altus, que é uma incentivadora do desenvolvimento tecnológico mundial, e cria um elo entre esta geração de produtos e os CLPs que estamos projetando para o futuro!